Ok after my baby feeling sorry for herself while i saved to buy her what she needed, well the clutch arrived on Tuesday but needs special bolts so have ordrered them and the new gearbox mounts for the 6 speed

While the engine bay was empty i thought i would install the gear linkage,

old one

new one

Linkages side by side

Only pitfall is i lose the Quick shift, ahh well !!

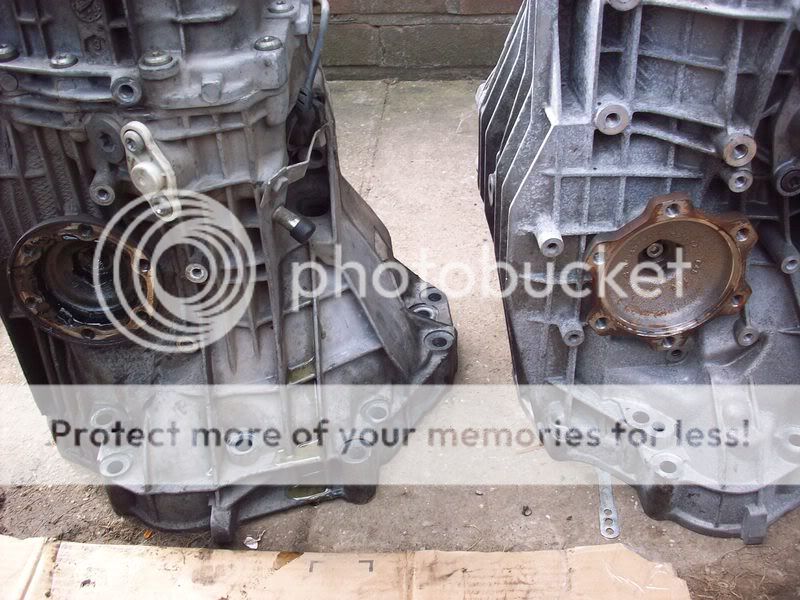

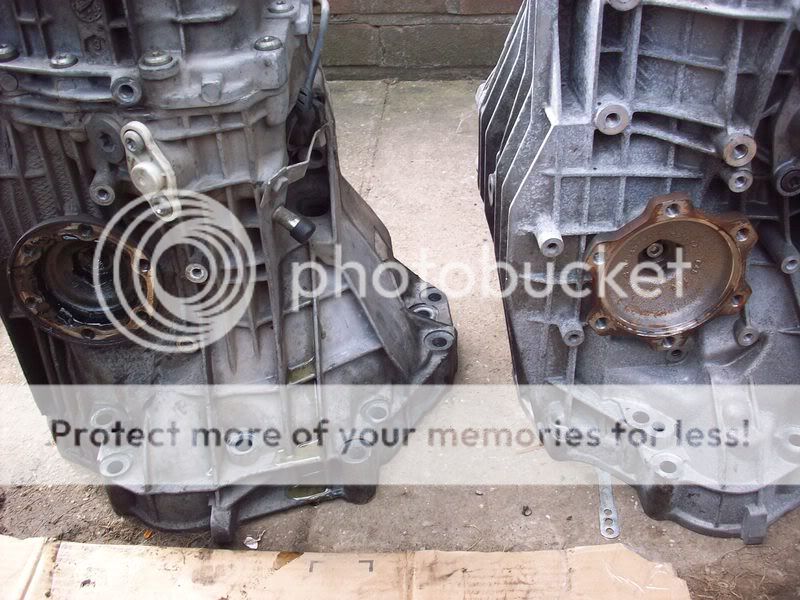

Differences between boxes, not a lot in length but the six speed must be at least 20kg heavier

The reverse switch was different so i hacked it apart to access the connectors to mount the old wiring on.

Now i am stuck as none of the 3 sets of shafts will work and i have no idea which ones would go straight in if any, so i am going to try to get the 130mm inners that fit the box machined to fit my original shafts. Anyone help here??

While the engine bay was empty i thought i would install the gear linkage,

old one

new one

Linkages side by side

Only pitfall is i lose the Quick shift, ahh well !!

Differences between boxes, not a lot in length but the six speed must be at least 20kg heavier

The reverse switch was different so i hacked it apart to access the connectors to mount the old wiring on.

Now i am stuck as none of the 3 sets of shafts will work and i have no idea which ones would go straight in if any, so i am going to try to get the 130mm inners that fit the box machined to fit my original shafts. Anyone help here??

00 ish but dont want to push it till i am sure of this shaft etc etc

00 ish but dont want to push it till i am sure of this shaft etc etc