- Joined

- Jul 25, 2011

- Messages

- 169

- Reaction score

- 75

- Points

- 28

- Location

- Rustington, West Sussex

- Website

- www.johnmitchellracing.co.uk

Hi all, I have had my S3 for three months now and have been busy tearing it down and rebuilding it back up the way I wanted it to be. Some of the tasks taken on we're not at all expected and others were planned upgrades. The work is reaching a near conclusion now so I thought I would share my story, for interest, info or just pure enthusiasm.

I bought this example from my good friend, who owned it from new having purchased it from Sterling Audi. A facelift S3 Sportback, 6spd in Sprint blue, with a fair measure of factory fitted options. With 54k on the clock we closed a deal at £14500, and I was a happy fella, having always admired this car.

I drove it back from Scotland to the warmer West Sussex coast, a pleasant drive but it did however highlight an immediate problem in that the diff was noisy. Still, I had an Audi extended warranty to cover this?

Following a closer inspection at our workshops highlighted my misplaced trust in this vehicle and its previous care. I should have listened to my own advice often afforded to my customers and looked before I leaped! So indeed I must take some responsibility in this unfortunate revelation. In addition to the failed Haldex diff I found the bonnet seams on the underside were rusting out due to poor factory prep, there was light corrosion found in the front and rear wheel arches caused by the liner rubbing, the rear floor pan had light corrosion at all the weld sites, the rear subframe was corroded and all the adjustment bolts were seized solid, the clutch was on it last legs, the gearbox main shaft bearing was worn to excess, the air con condenser was heavily damaged by multiple debris impacts, the Audi Techs had left sockets in the coolant reservoir, the dealer techs had also failed to re-fit all the retaining bolts for the cam belt cover after completing the renewal of same, the sills were damaged were dealer or tyre centre had used unprotected jack direct to the sill and not used the correct lifting points and so on it went . Well I was pretty deflated and wondering what I had done!

. Well I was pretty deflated and wondering what I had done!

First stop Audi Dealer to present claim for the rear diff noise, and bonnet corrosion. After a fight with Allianz who underwrite the Audi extended warranty I finally got a new rear diff and glad I was too as these are £2700.00 to buy. The bonnet however was not a success as after Audi checked the paint depth they informed me that it was too thick and clearly must have been painted post build. I was assured by my friend that this was not the case so indeed did it get repaired by dealer before handover?? Anyway I bit the bullet and bought a new genuine bonnet and had it painted. I stripped out the rear subframe and replaced it with a good condition used frame, which I stripped, shot blasted and powder coated my signature purple. The frame was then assemble with all new components which were also powder coated. I fitted the new rear diff into the frame and this was made ready to be re-installed.

The floor pan was next for some love. This I stripped back and painstakingly removed all the corrosion back to clean steel. Next I etch primed the floor pan. Following which I sprayed it into body colour and finished with a coat or two of 2 pack lacquer. Once cured the painted floor pan was sprayed with clear waxoyl, never to corrode again!

With the nice new paintwork the old exhaust heat shield looked decidedly tired so I bought a new one to replace it. I also deleted the redundant battery box and powder coated black the metal capping plate to give it better protection.

Next came some upgrades to put a little joy into proceedings and inject a little more purpose into the build. We are agents for both Milltek exhaust systems and KW suspension. So indeed it would have been rude not to fit a non resonated turbo back system with sport cat and a Variant 2 KW coil over kit and anti roll bars which compliment my purple subframe beautifully .

.

Works to the rear engineering were completed with the fitting of re-powder coated rear brakes and back plates, new cross drilled rear discs and pads, and new brake hoses.

My focus now turned to the front engineering and the front end of the car was stripped off to give ready access.

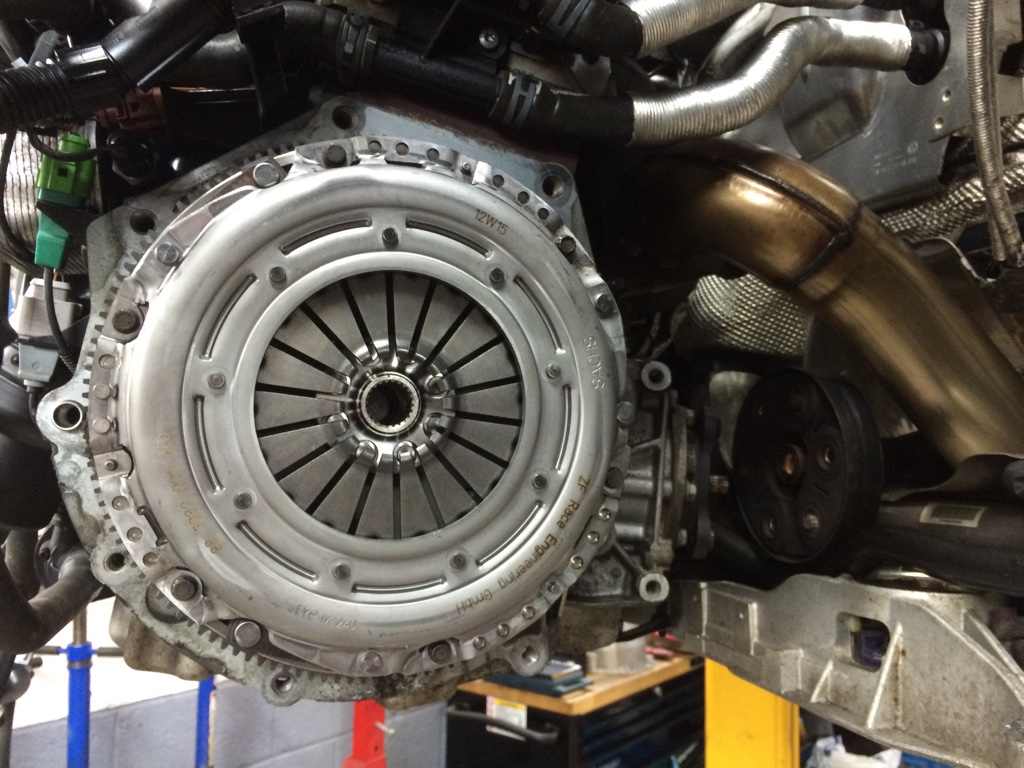

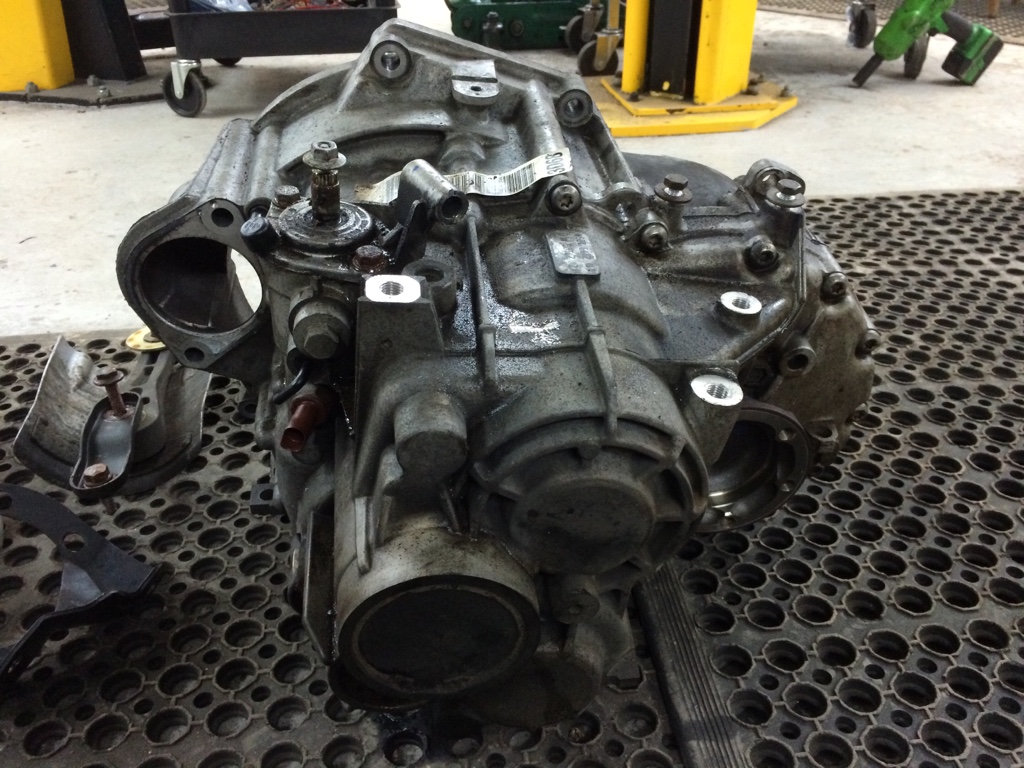

The gearbox was stripped out and the clutch and DMF removed. The gearbox was sent to our specialist rebuilder to have the main shaft bearing repair carried out and a full internal check for any other works required. Meanwhile I fitted a new LUK genuine DMF and Sachs uprated organic clutch in readiness for some Stage 2+ tuning.

I bought this example from my good friend, who owned it from new having purchased it from Sterling Audi. A facelift S3 Sportback, 6spd in Sprint blue, with a fair measure of factory fitted options. With 54k on the clock we closed a deal at £14500, and I was a happy fella, having always admired this car.

I drove it back from Scotland to the warmer West Sussex coast, a pleasant drive but it did however highlight an immediate problem in that the diff was noisy. Still, I had an Audi extended warranty to cover this?

Following a closer inspection at our workshops highlighted my misplaced trust in this vehicle and its previous care. I should have listened to my own advice often afforded to my customers and looked before I leaped! So indeed I must take some responsibility in this unfortunate revelation. In addition to the failed Haldex diff I found the bonnet seams on the underside were rusting out due to poor factory prep, there was light corrosion found in the front and rear wheel arches caused by the liner rubbing, the rear floor pan had light corrosion at all the weld sites, the rear subframe was corroded and all the adjustment bolts were seized solid, the clutch was on it last legs, the gearbox main shaft bearing was worn to excess, the air con condenser was heavily damaged by multiple debris impacts, the Audi Techs had left sockets in the coolant reservoir, the dealer techs had also failed to re-fit all the retaining bolts for the cam belt cover after completing the renewal of same, the sills were damaged were dealer or tyre centre had used unprotected jack direct to the sill and not used the correct lifting points and so on it went

. Well I was pretty deflated and wondering what I had done!

. Well I was pretty deflated and wondering what I had done!

First stop Audi Dealer to present claim for the rear diff noise, and bonnet corrosion. After a fight with Allianz who underwrite the Audi extended warranty I finally got a new rear diff and glad I was too as these are £2700.00 to buy. The bonnet however was not a success as after Audi checked the paint depth they informed me that it was too thick and clearly must have been painted post build. I was assured by my friend that this was not the case so indeed did it get repaired by dealer before handover?? Anyway I bit the bullet and bought a new genuine bonnet and had it painted. I stripped out the rear subframe and replaced it with a good condition used frame, which I stripped, shot blasted and powder coated my signature purple. The frame was then assemble with all new components which were also powder coated. I fitted the new rear diff into the frame and this was made ready to be re-installed.

The floor pan was next for some love. This I stripped back and painstakingly removed all the corrosion back to clean steel. Next I etch primed the floor pan. Following which I sprayed it into body colour and finished with a coat or two of 2 pack lacquer. Once cured the painted floor pan was sprayed with clear waxoyl, never to corrode again!

With the nice new paintwork the old exhaust heat shield looked decidedly tired so I bought a new one to replace it. I also deleted the redundant battery box and powder coated black the metal capping plate to give it better protection.

Next came some upgrades to put a little joy into proceedings and inject a little more purpose into the build. We are agents for both Milltek exhaust systems and KW suspension. So indeed it would have been rude not to fit a non resonated turbo back system with sport cat and a Variant 2 KW coil over kit and anti roll bars which compliment my purple subframe beautifully

.

.Works to the rear engineering were completed with the fitting of re-powder coated rear brakes and back plates, new cross drilled rear discs and pads, and new brake hoses.

My focus now turned to the front engineering and the front end of the car was stripped off to give ready access.

The gearbox was stripped out and the clutch and DMF removed. The gearbox was sent to our specialist rebuilder to have the main shaft bearing repair carried out and a full internal check for any other works required. Meanwhile I fitted a new LUK genuine DMF and Sachs uprated organic clutch in readiness for some Stage 2+ tuning.

.

.

.

.