Hi all, I'm looking to jack up the S4 and have measured that the pinch weld seems about an inch deep - what does everyone do with regard to the slotted / side lift jack pads? They never seem to be this deep - they seme to be 20mm at most.

Jack Pads

- Thread starter fast-ferret

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Apr 17, 2017

- Messages

- 206

- Reaction score

- 110

- Points

- 43

I got a Halfords low profile jack. I bought a rubber pad off eBay. It's same size just doesn't have the slot. It's ok for time being and doesn't damage anything but I'd like to get a rubber puck with the slot in it.Hi all, I'm looking to jack up the S4 and have measured that the pinch weld seems about an inch deep - what does everyone do with regard to the slotted / side lift jack pads? They never seem to be this deep - they seme to be 20mm at most.

Sent from my SM-G950F using Tapatalk

I used a ice hockey Puck and cut a groove in it.

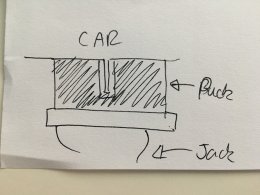

But the pinch weld is about an inch deep - I'm right in saying that the slot should be deep enough so that the raised bits are flush with the car right? Like this amazing diagram wot I have drawn (attached).

A puck isn't deep enough to cut an inch slot is it?

Attachments

30mm jack puck ebay no. - 273016638623

JG

Oh ok that one is deep enough. Something worries me about them though - they are quite literally two ice hockey pucks glued together and with a slot cut in them. Isn't that a bit heath robinson?

Oh ok that one is deep enough. Something worries me about them though - they are quite literally two ice hockey pucks glued together and with a slot cut in them. Isn't that a bit heath robinson?

Thought it looked ok, but if you question it's strength it's not worth the money.

JG

Thought it looked ok, but if you question it's strength it's not worth the money.

JG

I’m not saying I’m correct in my doubts - I’ve never used one of these things. It might be absolutely spot on but it seems odd on the surface of it

Sent from my iPhone using Tapatalk

Here's what I use. Can't remember where I bought it, but it's specifically heavy duty, made in Slovakia and has the word Vegum on it. Works well on an 2-tonne trolley jack as that has a decent pad width.

I'd check for more details, but it's currently holding my wife's i3 in mid air while I get one of the alloys refurbished!

I'd check for more details, but it's currently holding my wife's i3 in mid air while I get one of the alloys refurbished!

Here's what I use. Can't remember where I bought it, but it's specifically heavy duty, made in Slovakia and has the word Vegum on it. Works well on an 2-tonne trolley jack as that has a decent pad width.

I'd check for more details, but it's currently holding my wife's i3 in mid air while I get one of the alloys refurbished!

View attachment 161924

Looks like a hockey puck too (well, 2 hockey pucks). Maybe they’re fine, just sounds odd!

Sent from my iPhone using Tapatalk

Scatter lots of cash and buy a couple of pairs of Jackpoint jack stands, that is what I did as soon as I bought my B8 S4, they are so easy to use especially if you have a couple of trolley jacks, I always lift one side at a time using 2 trolley jacks to avoid stressing the frame. I joined a group of like minded people on a Porker forum and we got a very good deal and a stupidly good deal on freighting by air, about 26 hours from collection at factory to landing in UK and out through customs - Royal Mail etc could not do that internally in UK!

Scatter lots of cash and buy a couple of pairs of Jackpoint jack stands, that is what I did as soon as I bought my B8 S4, they are so easy to use especially if you have a couple of trolley jacks, I always lift one side at a time using 2 trolley jacks to avoid stressing the frame. I joined a group of like minded people on a Porker forum and we got a very good deal and a stupidly good deal on freighting by air, about 26 hours from collection at factory to landing in UK and out through customs - Royal Mail etc could not do that internally in UK!

Just looked at them, very smart - I would love a couple, but I'm not spending that much on them

I can't work out why someone else has not made cheaper versions out of steel, these Jackpoint ones are brilliant, they don't take up much room in the garage as they stack and I've added wooden blocks on to the normal top sections to help spread the load and rubber lined all the wood so no paintwork damage occurs. With 2 sets, I can get the car up in the air within a few minutes, okay it takes extra time to slacken the wheel bolts off, used them twice this year on my car, once to swop winter/summer wheels/tyres and again to replace all the brake fluid.

I can't work out why someone else has not made cheaper versions out of steel, these Jackpoint ones are brilliant, they don't take up much room in the garage as they stack and I've added wooden blocks on to the normal top sections to help spread the load and rubber lined all the wood so no paintwork damage occurs. With 2 sets, I can get the car up in the air within a few minutes, okay it takes extra time to slacken the wheel bolts off, used them twice this year on my car, once to swop winter/summer wheels/tyres and again to replace all the brake fluid.

They do look great and I'm probably one of the first to spend money on stuff I seldom use, but even given that I'm thinking hmm - my axle stands would be worth about 8 times the cost of my jack, and that's just for a pair! I must admit I thought you were more bonkers than I now do as I read the site and realised it's $299 a pair, not each, so that's a bit better...

But still, I feel like I've got to justify it

Agree it's odd that no alternative exists, that's the first thing I looked for after seeing those...

Having thought a bit more about this, I feel like this topic is far more confusing than it should be  I've settled with the idea of getting the hockey puck jack pad, so that's that bit done, but now I am faced with questions:

I've settled with the idea of getting the hockey puck jack pad, so that's that bit done, but now I am faced with questions:

On a related note - I can't seriously see any mechanic going to anywhere near these lengths to protect the pinch weld, and on inspection underenath the car I can see the plastic tray near it is broken anyway and the weatherproofing has come away a bit, so I suppose that answers my question - no they don't take these precautions, or at least not all of them, so then that makes me wonder why I would bother? I'll never avoid having to go to a mechanics and then they'll just slap a lift under there without any of these precautions and it'll be messed up anyway!

- The base of the eBay puck is too large (75mm) for the flat pad on my jack (45mm). I have the SGS Low Profile 2 ton jack. The eBay seller makes a flat jack pad which has a 60mm diameter. Do I either:

- (a) Use the 45mm SGS flat pad and put the eBay hockey put on top and left it overhang

- (b) Take off the SGS flat pad and just put the eBay hockey puck on top of the bumpy metal jack saddle

- (c) get the eBay sellers 60mm flat jack pad as well as the hockey puck, and use both?

- Once the car is jacked up I need to use axle stands, where do I put them? This seems to be a common dilemma (hence the jackpoint stands) which seems kind of ridiculous. This seems like such a mundane problem to have that I feel like I must be overthinking things somewhere! It feels preferable to place the axle stands in the same place as the jacking point (at the pinch weld) but I imagine they won't fit (I've seen others saying they don't) so then where do I put them? If I do somehow manage to put them where the pinch weld is then I should also be getting the same slotted hockey puck for my axle stands as well I presume? That then goes in to a whole other series of questions because my jack stands are the SGS 4 ton ratchet stands and the top wouldn't accomodate the puck, although eBay man can come to the rescue here with an increasingly bizarre and home made contraption of an axle stand top

On a related note - I can't seriously see any mechanic going to anywhere near these lengths to protect the pinch weld, and on inspection underenath the car I can see the plastic tray near it is broken anyway and the weatherproofing has come away a bit, so I suppose that answers my question - no they don't take these precautions, or at least not all of them, so then that makes me wonder why I would bother? I'll never avoid having to go to a mechanics and then they'll just slap a lift under there without any of these precautions and it'll be messed up anyway!

When I first splashed out maybe £25K on my S4 when it was almost 2.5 years old, I immediately set about buying a set of reasonable used 18" Audi A4 B8 alloys for use with winter tyres. Then I looked under the car and though, "how do you lift it up and keep it up safely" - after many many hours on the internet I bumped into a Porsche forum that were actively setting out to get a good deal on these Jackpoint jack stands from the owner of that company, the group buy went through and so was closed but one or two people came into this late and managed to set up the next group buy, I leapt into that one ASAP as I could see that this was my one and only chance to buy these at a "reasonable" price, in fact maybe I contacted the Jackpoint guy direct and it was he who suggested that I joined the UK Porsche forum and join their group buy, anyway, I've got no regrets on that purchase that just make life so easy and safer, use them on my wife's Polo as well. Only issue with the Polo was, I did not look well enough at the profile of the body at the jacking points and the rear ones, I think, splay out quite quickly, so the Jackpoint top sections, even although I've modified them by bonding wood and rubber onto them, ended up gripping the Polo underbody and shearing the combination of soft stone guard paint and body paint so on one side there is a loose section of metalwork covering that needs sorting before winter.

On the topic of workshops causing damage near or at the jacking points on the sills, before last winter, I applied many coats of Hammerite paint in roughly body colour to these 4 lifting areas. I know Hammerite says never ever mix 2 or 3 of their paints together as they might not behave well, but I did, and mixed blue and black, the resulting colour looks okay.

I keep meaning to be brave enough to ask the VW dealership exactly how they lift these cars, but it looks like they just lift at the base of the folded welded area and not as I and you are trying to do which is use the vertical section as a steadying aid and lift on the flat surface above.

Edit:- once I tried to beat the AA to my wife's car, she phoned to say there was a horrid noise which I thought would be stone(s) trapped in the brakes, so as we have AA cover, I got her to call them in. The guy just placed the jack roughly near the correct area and lifted - okay in his mind any damage is low down so how will notice??

On the topic of workshops causing damage near or at the jacking points on the sills, before last winter, I applied many coats of Hammerite paint in roughly body colour to these 4 lifting areas. I know Hammerite says never ever mix 2 or 3 of their paints together as they might not behave well, but I did, and mixed blue and black, the resulting colour looks okay.

I keep meaning to be brave enough to ask the VW dealership exactly how they lift these cars, but it looks like they just lift at the base of the folded welded area and not as I and you are trying to do which is use the vertical section as a steadying aid and lift on the flat surface above.

Edit:- once I tried to beat the AA to my wife's car, she phoned to say there was a horrid noise which I thought would be stone(s) trapped in the brakes, so as we have AA cover, I got her to call them in. The guy just placed the jack roughly near the correct area and lifted - okay in his mind any damage is low down so how will notice??

This has been a thread and a half for me. I have no idea how to jack up my car (sorry). Who knew there were so many options.

****** ridiculous if you ask me, I wish there was one way which was easy and well documented and didn’t require some amazing jack stands which I can’t afford!

Sent from my iPhone using Tapatalk

Those jackstands look the business.

I've got a Arcan 2-tonne trolley jack similar to the one pictured here. Very easy to use considering I used to use a 1.5 tonne Halfords jack for many years. Key thing is a wide lifting pad so that the jack pad can sit in the centre, not overhanging. I always use an axle stand in addition. Couple of blocks of timber to chock the wheels, and Bob's your uncle!

I've got a Arcan 2-tonne trolley jack similar to the one pictured here. Very easy to use considering I used to use a 1.5 tonne Halfords jack for many years. Key thing is a wide lifting pad so that the jack pad can sit in the centre, not overhanging. I always use an axle stand in addition. Couple of blocks of timber to chock the wheels, and Bob's your uncle!

It would make life so much easier if there was a third jack point/pinch weld somewhere in the middle of each sill. You could then lift the full side in 1 and get 2 stands under in 1 go.

- Joined

- Nov 24, 2016

- Messages

- 440

- Reaction score

- 310

- Points

- 63

It would make life so much easier if there was a third jack point/pinch weld somewhere in the middle of each sill. You could then lift the full side in 1 and get 2 stands under in 1 go.

I presume there definitely isn’t a third front jacking point? I briefly looked and seemed to find there wasn’t but didn’t investigate a huge amount.

Sent from my iPhone using Tapatalk

I’d doubt if there is a strong point mid way alone, from Audi’s point of view “what is your problem, just bring it in to us”.

I still have a very old Halfords 1.5 Ton trolley jack that never gets used nowadays but is still in good working condition. My car lifting trolley jacks are Sealey and same item from Clarke, low enough Min height and high enough Max height long frame versions. I also seem to have a couple of small short frame trolley jacks as well for supporting bits when working on cars, along with a couple of small bottle jacks and a single scissors jack, all good stuff to have if you are serious about working on cars! Still have a couple of pairs of axle stands but not really found any use for them now, oh and a couple of sets of long wide high fabricated wooden ramps, my old nasty steel ramps went into recycling steel skip some time ago.

Since buying my second long frame proper diyer trolley jack, I have made a point of never lifting a car at a single point, now I lift they at one side using one hand on each of the trolley jacks, then place the stool part of the jack stands under the top part on the trolley jack.

Okay if I am just swopping summer/winter tyres I’ll play unsafe and quickly lift and swop wheels, but I know that I’m not being very clever!

I still have a very old Halfords 1.5 Ton trolley jack that never gets used nowadays but is still in good working condition. My car lifting trolley jacks are Sealey and same item from Clarke, low enough Min height and high enough Max height long frame versions. I also seem to have a couple of small short frame trolley jacks as well for supporting bits when working on cars, along with a couple of small bottle jacks and a single scissors jack, all good stuff to have if you are serious about working on cars! Still have a couple of pairs of axle stands but not really found any use for them now, oh and a couple of sets of long wide high fabricated wooden ramps, my old nasty steel ramps went into recycling steel skip some time ago.

Since buying my second long frame proper diyer trolley jack, I have made a point of never lifting a car at a single point, now I lift they at one side using one hand on each of the trolley jacks, then place the stool part of the jack stands under the top part on the trolley jack.

Okay if I am just swopping summer/winter tyres I’ll play unsafe and quickly lift and swop wheels, but I know that I’m not being very clever!

- Joined

- Jan 22, 2003

- Messages

- 2,163

- Reaction score

- 1,433

- Points

- 113

There are quite a few threads on Audizine on this subject (and plenty of tales of crushed pinch welds  ). From memory most of them use the "slotted puck" method, but the jack stands in @spartacus 68 's post are popular too.

). From memory most of them use the "slotted puck" method, but the jack stands in @spartacus 68 's post are popular too.

Just... well wow at this thread lol

Having not really bothered to look under this A4 or even my old 2wd A4 i cant really comment on where the lift point actually is.

However, personally i use an ex RAC 2 ton high lift jack an usually lift from the pinch point. Never bothered with any kind of puck etc ever at all an never caused any detrimental damage. Even when lifting an entire side 3ft off the floor. I just use the standard rubber pad thats attached to jack since ive owned it.

Having not really bothered to look under this A4 or even my old 2wd A4 i cant really comment on where the lift point actually is.

However, personally i use an ex RAC 2 ton high lift jack an usually lift from the pinch point. Never bothered with any kind of puck etc ever at all an never caused any detrimental damage. Even when lifting an entire side 3ft off the floor. I just use the standard rubber pad thats attached to jack since ive owned it.

So, CarbonMike, after lifting the car up, how do you support it so that you can get in under the car to work on it?

Axle stands on the box section chassis rails.

You can lift and or support most monocoque chassis vehicles from just about any box sectioned area of the chassis.

Edit: and just to add before i forget... the rear can be lifted safely by jacking from the diff cradle if 4wd.

Most cars these days, the lower suspension arms have a domed rectangle pressed into them. There designed to be used as an axle stand point too.

You can lift and or support most monocoque chassis vehicles from just about any box sectioned area of the chassis.

Edit: and just to add before i forget... the rear can be lifted safely by jacking from the diff cradle if 4wd.

Most cars these days, the lower suspension arms have a domed rectangle pressed into them. There designed to be used as an axle stand point too.

Last edited:

Interesting answer to my question, but how do you find were the box sections are on a car that is covered up underneath with plastic covers?

Not sure that I've spotted any of these "domed rectangle pressed into them" on my B8 S4 either.

Edit:- maybe time for you to get down and dirty and check things out?

Not sure that I've spotted any of these "domed rectangle pressed into them" on my B8 S4 either.

Edit:- maybe time for you to get down and dirty and check things out?

The box sections meet up with the sill panels behind front wheel and infront of rear wheel. One of the strongest local areas to lift from, thats why a garage will position a 2 poster lift there.

Nowhere did i state that EVERY car has a stand point on a lower arm.

I work with race, rally and Formula cars as a day job and a hobby and have done for nearly 15 years... jacking up a car really isnt this hard.

Nowhere did i state that EVERY car has a stand point on a lower arm.

I work with race, rally and Formula cars as a day job and a hobby and have done for nearly 15 years... jacking up a car really isnt this hard.

Generic Google image search for jacking up a 2014 Audi A4

Its not rocket salad ***...

Yeh but that search is kindof a case in point. I did that and found that only one the results was relevant, and that only told me what I already knew.

In your image there are images for:

- An A4 B7

- An A4 B8

- An A3

- A TT

The A4 B8 one only confirms the side view which we already know.

Sent from my iPhone using Tapatalk

And the B7 underside isnt all that dis-similiar to a B8. Or even an A3 i think. Or just about any modern car with Y shaped lower suspension arms (as oppose to old skool straight arms that use a tie bar setup, for those that even know what they were...)

Best place i can see for axle stand is where bottom arms join chassis. First google picture with red arrows on I believe.

Best place i can see for axle stand is where bottom arms join chassis. First google picture with red arrows on I believe.

Last edited:

Reality is, this section and thread was about lifting B8 S4, not anything else with a clearly exposed under frame, still to the thread please when adding advice.

Resurrecting an old thread here but I've seen another set of stands that solves the same problem as the jackpoint stands, they don't look as strong in my opinion but looks is probably a pretty bad way of measuring the strength of something  and they do have good reviews...

and they do have good reviews...

Here they are -> https://safejacks.com/products/the-rennstand-by-safe-jack-single-unit

Ever seen those @rum4mo ?

Here they are -> https://safejacks.com/products/the-rennstand-by-safe-jack-single-unit

Ever seen those @rum4mo ?

No, maybe they were not around when I was looking for a solution back in 2013, I agree they do not seem to inspire a lot of confidence, but seeing is believing. Strangely, it was a group called Rennlist that started the interest in the ones I eventually bought. I would be concerned that these ones do not seem to offer much in the way of side to side stability, but as I say maybe they are okay in the flesh.

Edit:- I can see these jack stands as being a good solution if you used them on a car where they got securely fixed to the side rails of the car , not just resting the car on the top of them.

Edit:- I can see these jack stands as being a good solution if you used them on a car where they got securely fixed to the side rails of the car , not just resting the car on the top of them.

No, maybe they were not around when I was looking for a solution back in 2013, I agree they do not seem to inspire a lot of confidence, but seeing is believing. Strangely, it was a group called Rennlist that started the interest in the ones I eventually bought. I would be concerned that these ones do not seem to offer much in the way of side to side stability, but as I say maybe they are okay in the flesh.

Edit:- I can see these jack stands as being a good solution if you used them on a car where they got securely fixed to the side rails of the car , not just resting the car on the top of them.

I’m not sure how wide they are - the pictures may be deceiving.. they do go higher than the jackpoint stands but can be higher or lower, obviously lower will be more stable.

When you say you see them as good if they fixed to the side rails - aren’t they the same as any jack stand in this regard, jackpoint included? They have a pinch weld pad which sits on top of the stands and locks in with a thick pin so it won’t go anywhere, and as it’s a pinch weld pad the car isn’t going to go anywhere, the only concern I can see is the lateral stability of the stand (and as above - I’m not sure if that’s valid).

Yes I saw your posts on rennlist and these indeed came from the same forum. It seems those Porsche guys like to be able to jack their cars up properly! I assume the name came from the name of the forum. The stands seem well received on the forum.

Tempted to set up a group buy for them - I worked it out at £218 for a pair if 10 people each bought a pair. How much were your jackpoints from the group buy? I couldn’t see a price mentioned in the thread.

Sent from my iPhone using Tapatalk

I'd reckon that my Jackpoint jack stands would have been nearer £600 for 2 pairs - and that was a group buy.

What concerns me, and remember that I'm trying to be critical but in a constructive way as I have already bought something else, is that these look okay when the car is up on all four stands, getting it up from only one side to both sides, for me looks like it would end up going through an unstable state, which is not too good.

As I said, if these cars had dedicated threaded holes provided for these stands top adaptors to bolt to tightly, and the adaptors bolted tightly to the top bars, then I'd be happier to buy/use them, also is the base contact points were arched to tolerate the car being lifted on one side then the other it would be okay I'd think - just having these small 2 flat ends of the legs in contact with the floor on each stand and then tilting the car on the second set does not look like being the best idea.

Having said that, they do look very flexible and very compact to store - but mainly these sorts of things would live in a garage when not in use and my Jackpoint jack stands stack on top of each other. I'd consider that as they are, they make a very good starting point as a "phase A" of a jacking stand design, also it sounds like you are smart enough not to mess with them and use some of their parts for other uses - that is always the issue with DIYers and bits of kit and come in many removable parts!

I'd rather they had a "ringed" base structure still fabricated from U section steel with a slot in the front to allow access for a jack, that would make me give them the thumbs up - okay that means more like Jackpoint jack stand design which I like, and also make them more bulky to carry in the car and store, but that, in my mind, is a small price to pay for safety.

What concerns me, and remember that I'm trying to be critical but in a constructive way as I have already bought something else, is that these look okay when the car is up on all four stands, getting it up from only one side to both sides, for me looks like it would end up going through an unstable state, which is not too good.

As I said, if these cars had dedicated threaded holes provided for these stands top adaptors to bolt to tightly, and the adaptors bolted tightly to the top bars, then I'd be happier to buy/use them, also is the base contact points were arched to tolerate the car being lifted on one side then the other it would be okay I'd think - just having these small 2 flat ends of the legs in contact with the floor on each stand and then tilting the car on the second set does not look like being the best idea.

Having said that, they do look very flexible and very compact to store - but mainly these sorts of things would live in a garage when not in use and my Jackpoint jack stands stack on top of each other. I'd consider that as they are, they make a very good starting point as a "phase A" of a jacking stand design, also it sounds like you are smart enough not to mess with them and use some of their parts for other uses - that is always the issue with DIYers and bits of kit and come in many removable parts!

I'd rather they had a "ringed" base structure still fabricated from U section steel with a slot in the front to allow access for a jack, that would make me give them the thumbs up - okay that means more like Jackpoint jack stand design which I like, and also make them more bulky to carry in the car and store, but that, in my mind, is a small price to pay for safety.

I'd reckon that my Jackpoint jack stands would have been nearer £600 for 2 pairs - and that was a group buy.

What concerns me, and remember that I'm trying to be critical but in a constructive way as I have already bought something else, is that these look okay when the car is up on all four stands, getting it up from only one side to both sides, for me looks like it would end up going through an unstable state, which is not too good.

Looking at them they seem wider width wise than a standard axle stand and obviously a lot longer so I reckon they should be more stable than a normal stand. Not as stable I imagine as the jackpoints though - those things look like they’d support a car in an earthquake!

As I said, if these cars had dedicated threaded holes provided for these stands top adaptors to bolt to tightly, and the adaptors bolted tightly to the top bars, then I'd be happier to buy/use them

They’ll be the same as the jackpoints or any axle stand here though right? They have a top pad which has a pinch weld holder so the car definitely isn’t going to move off the pad (note I’ve seen some guy in YouTube jacking his car up with them without any top pad which seems very dangerous!! I definitely wouldn’t do that) and the top pad secures to the top bar of the stand with a pin, so the pad isn’t going anywhere either. That seems secure to me.

also is the base contact points were arched to tolerate the car being lifted on one side then the other it would be okay I'd think - just having these small 2 flat ends of the legs in contact with the floor on each stand and then tilting the car on the second set does not look like being the best idea.

I think the jackpoints would win on stability but they are super sturdy looking, these look more sturdy (to me at least) than a standard stand.

Having said that, they do look very flexible and very compact to store - but mainly these sorts of things would live in a garage when not in use and my Jackpoint jack stands stack on top of each other. I'd consider that as they are, they make a very good starting point as a "phase A" of a jacking stand design, also it sounds like you are smart enough not to mess with them and use some of their parts for other uses - that is always the issue with DIYers and bits of kit and come in many removable parts!

Someone else rightly mentioned the prospect of losing a pin and putting something inadequate in its place, it’s a valid concern I think. I suppose the size is useful but as you say - not a huge win.

I'd rather they had a "ringed" base structure still fabricated from U section steel with a slot in the front to allow access for a jack, that would make me give them the thumbs up - okay that means more like Jackpoint jack stand design which I like, and also make them more bulky to carry in the car and store, but that, in my mind, is a small price to pay for safety.

That would be more sturdy I imagine yeh, I think I’m happy with how sturdy they look, not to the level of jackpoint but still look good to me.

I’ve set up a group buy if anyone is interested - would need to buy 20 (so 10 pairs or 5 lots of 4). £226 for two or £444 for four.

https://www.audi-sport.net/xf/threa...roup-buy-20-off-and-combined-shipping.378478/

Sent from my iPhone using Tapatalk

Last edited:

As I said, remember I am looking at this design having already bought something else which does the same job.

I'm amazed that no one in Europe or even UK has not come up with a "local" tool for this job, its just crazy to me, cars have moved on so much in what you need to safely get them up in the air, but the tool companies, and even the bespoke lifting and holding companies that appear in serious car mags are still using older chunkier/clunkier and in some cases unsuitable solutions, if there had been a well designed UK based solution 5 years ago, that would have been what I bought.

Good luck with the group buy, smart buyers should be going for enough to get the car completely up off the ground. Sometimes the air freighters have amazing deals taking stuff from USA to UK, there will be import duty to pay as well but the international air freighters tend to handle that for you and collect payment in a sort of COD basis.

Edit:- actually despite what you have written in the group buy, I'd say these look a lot cooler than my Jackpoint jack stands, I like things to "say" what they do, a bit like comparing "French gears" with "enclosed hub gears" on push bikes - I'd go for the exposed ones every time for coolness!

Another Edit:- the import due costs will not be something that should put anyone off buying these items, it will be punitive from memory.

I'm amazed that no one in Europe or even UK has not come up with a "local" tool for this job, its just crazy to me, cars have moved on so much in what you need to safely get them up in the air, but the tool companies, and even the bespoke lifting and holding companies that appear in serious car mags are still using older chunkier/clunkier and in some cases unsuitable solutions, if there had been a well designed UK based solution 5 years ago, that would have been what I bought.

Good luck with the group buy, smart buyers should be going for enough to get the car completely up off the ground. Sometimes the air freighters have amazing deals taking stuff from USA to UK, there will be import duty to pay as well but the international air freighters tend to handle that for you and collect payment in a sort of COD basis.

Edit:- actually despite what you have written in the group buy, I'd say these look a lot cooler than my Jackpoint jack stands, I like things to "say" what they do, a bit like comparing "French gears" with "enclosed hub gears" on push bikes - I'd go for the exposed ones every time for coolness!

Another Edit:- the import due costs will not be something that should put anyone off buying these items, it will be punitive from memory.

Last edited:

mermade

Registered User

Powerflex now do poly jack pad adaptors

https://powerflexstore.co.uk/audi/a...ck-pad-adaptor-a4-quattro-2008-2016-pf3-1660/

https://powerflexstore.co.uk/audi/a...ck-pad-adaptor-a4-quattro-2008-2016-pf3-1660/