Mk1 TT 225 track day car, Officially a ten second car 10.8 seconds at 127 mph.

- Thread starter desertstorm

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I've been reading this thread for a while and it's brilliant.

Full credit to you chap for such an inspiring project and one with such a rewarding end result.

So many projects just never reach an endpoint let alone a successful one.

top marks, only wish I could do such a project.

Full credit to you chap for such an inspiring project and one with such a rewarding end result.

So many projects just never reach an endpoint let alone a successful one.

top marks, only wish I could do such a project.

Haven't updated the thread for a little bit. Did another track day at Bedford with the revised position of the DSG cooler rad to keep the temps down. Also had tweaked the DSG mapping.

.

A little bit late as these videos were from a trackday at the end of July. Surprised to see Lee Whithead there and nice to finally meet him. Nice to get some feedback from somebody with a "serious" track TT. The day was a bit of a test for the DSG gearbox. On the previous track day at Mallory I didn't do that much running before the car had an issue with the wheel bearing and the DSG cooling wasn't good.

So here I was running with modified cooling for the DSG and only running 1.5bar boost 95% of the time, going to 1.8bar on the long straights with the push to pass.

Car is plenty fast enough at this. With the top map running 2 bar probably would have been close to 150mph on the 1km straight.

Car ran really well, DSG oil temps seemed to be pretty good with a maximum reading seen all day around 124 degrees, but typically around 100-110 degrees which I am happy with.

Extra exhaust silencer seemed to work, never got pinged at all for a noisy exhaust.

Bought a cheap Nextbase reconditioned camera off Fleabay. Has built in GPS speed and is time stamped so you can easily work out lap times to the nearest second. Also you don't have to remember to turn it on and off . Seems to work well, the pictures on this are a bit dark as the camera is looking through the tint at the top of the screen.

https://www.ebay.co.uk/itm/113867505225?

Uploaded some videos .

Following Lee around the track for a bit .

https://youtu.be/b7-Ij15DiaE

Overtook this Factory Leon Cupra race car a few times, think he was trying a little too hard to stop it happening again. It was a Pukka car on full slicks so surprised it spun that easily.

https://youtu.be/ihP5NgikAwg

Overtaking queues of cars is quite easy even when the one at the front is an M3.

https://youtu.be/wbGEXI9GR98

And caught this M4 with an older full track spec M3 in front. Thought the M4 was going to let me through when he ran out wide. Good job I hung back a bit. Easy overtake on the straight .

https://youtu.be/1DIcb-qs68A

Lees track day TT.

.

A little bit late as these videos were from a trackday at the end of July. Surprised to see Lee Whithead there and nice to finally meet him. Nice to get some feedback from somebody with a "serious" track TT. The day was a bit of a test for the DSG gearbox. On the previous track day at Mallory I didn't do that much running before the car had an issue with the wheel bearing and the DSG cooling wasn't good.

So here I was running with modified cooling for the DSG and only running 1.5bar boost 95% of the time, going to 1.8bar on the long straights with the push to pass.

Car is plenty fast enough at this. With the top map running 2 bar probably would have been close to 150mph on the 1km straight.

Car ran really well, DSG oil temps seemed to be pretty good with a maximum reading seen all day around 124 degrees, but typically around 100-110 degrees which I am happy with.

Extra exhaust silencer seemed to work, never got pinged at all for a noisy exhaust.

Bought a cheap Nextbase reconditioned camera off Fleabay. Has built in GPS speed and is time stamped so you can easily work out lap times to the nearest second. Also you don't have to remember to turn it on and off . Seems to work well, the pictures on this are a bit dark as the camera is looking through the tint at the top of the screen.

https://www.ebay.co.uk/itm/113867505225?

Uploaded some videos .

Following Lee around the track for a bit .

https://youtu.be/b7-Ij15DiaE

Overtook this Factory Leon Cupra race car a few times, think he was trying a little too hard to stop it happening again. It was a Pukka car on full slicks so surprised it spun that easily.

https://youtu.be/ihP5NgikAwg

Overtaking queues of cars is quite easy even when the one at the front is an M3.

https://youtu.be/wbGEXI9GR98

And caught this M4 with an older full track spec M3 in front. Thought the M4 was going to let me through when he ran out wide. Good job I hung back a bit. Easy overtake on the straight .

https://youtu.be/1DIcb-qs68A

Lees track day TT.

Time for another mammoth post,It's intercooler upgrade time.

The IC I have on my car was fitted when it was running around 275bhp on a stage 2 map. At that power it worked fine and has done many track days on the big turbo running 500bhp but I knew it was probably causing a larger pressure drop than was good. So rather than just replace it with something bigger and hope it improved decided to try and measure the pressure drop across the piping and the whole intake system from the turbo to the manifold.

Ordered a second hand DPF pressure sensor off Fleabay 076906051B with a connector attached for £12 and configured a map on input 3 and wired it to the MAF input as my car is running speed density. Sensor is measuring pressure drop between the exit of the turbo and the intake manifold, so the whole intake system.

There was around 5 PSI max drop across the intake system on the top map, As I thought not good.

Logging the pressure drop just across the 62mm intake pipes on the turbo side of the intercooler which was 1.75 M long and had 3 sweeping 45/60 bends , 1 sweeping 90 bend and 2 tight 90 degree bends The maximum I saw was 0.1 PSI ,add the shorter length of piping on the manifold side of the IC and the throttle body I bet there was no more than 0.25 PSI in the intake piping.

Pressure drop is measured in Kpa, there is a 2.4 Kpa offset on the sensor so you need to deduct 2.4 Kpa from the values.

Original intercooler was a Boost products 600x300 x62.5mm tube and fin IC. After searching around for suitable replacements which would fit I decided on a Treadstone TR1035. This is a slightly smaller version of the IC that Germain has fitted, a little shorter only 11 inches high rather than 12.5 on the bigger TR1235. With 15 rows across the IC as opposed to 17 on the TR1235 about 13% less area to flow through but I am not shooting for 650-700 bhp.

Also the larger TR1235 won't fit on my car with the oil cooler and DSG rad located where they are. The new IC is 90mm thick so substanially thicker than the existing item.

New intercooler is a bar and plate with a turning vane in the end tank to force 50% of the air through the top half of the intercooler.

The old IC is a tube and fin item

New intercooler with the turning vane in the end. Has 3 inch connections on the end as opposed to 2.5 inch on the Boost products item.

Old and new IC together. You can see the old one is a lot thinner.

Intercooler decided upon and ordered it took over 3 weeks to arrive from Turbozentrum in Germany. I had figured out before it arrived how I was going to mount it as I still have the alloy crash bumper which I use to hang the splitter off when that's fitted on track. I remove the number plate on track and there are many holes behind this which feed loads of air to the top of the IC.

Ordered a black 90 degree and 45 degree 63-75mm reducer hose to connect to the existing piping and blue items turned up ?. These had been sent 3 times with the first two being lost apparently, Not having much luck with ordering stuff at the moment.

Intercooler fits with not a not of room left. If I didn't have an oil cooler rad or DSG rad in between the radiator and the IC I could have mounted it further back.

All fitted, took the car for some test runs, immediately the car felt like it picked up quicker and felt a bit more urgent.

The pressure difference has halved and now peaks around 2.4-2.5 PSI. This means the turbo is running slower to deliver the same target boost, typically it's running 5-6K RPM less to make the same boost. I have had to tweak the Intergrator Max tables as the turbo was overboosting on spool but easily sorted.

Cooling performance isn't quite as good as the old IC on the two logs before and after, that was down to the fact that the new IC was shorter than the old one so isn't seeing any airflow at all with the number plate in. I have improvised a scoop to push some air down to the top of the IC and it's a lot better. I am 100% sure when on track with the number plate removed it will be a lot better than than the old IC. The new IC has a plate that diverts 50% of the incoming air to the top of the IC which helps to reduce pressure loss and stops the bottom part of the IC heat soaking.

Took the car for a spin doing some Dragy testing 100-200 Km/h and managed a 7.18s which is about 0.25s faster than my previous best so it's definitely faster. You can even see that in the logs between 110 and 170km/h it's around 0.2s faster.

The IC I have on my car was fitted when it was running around 275bhp on a stage 2 map. At that power it worked fine and has done many track days on the big turbo running 500bhp but I knew it was probably causing a larger pressure drop than was good. So rather than just replace it with something bigger and hope it improved decided to try and measure the pressure drop across the piping and the whole intake system from the turbo to the manifold.

Ordered a second hand DPF pressure sensor off Fleabay 076906051B with a connector attached for £12 and configured a map on input 3 and wired it to the MAF input as my car is running speed density. Sensor is measuring pressure drop between the exit of the turbo and the intake manifold, so the whole intake system.

There was around 5 PSI max drop across the intake system on the top map, As I thought not good.

Logging the pressure drop just across the 62mm intake pipes on the turbo side of the intercooler which was 1.75 M long and had 3 sweeping 45/60 bends , 1 sweeping 90 bend and 2 tight 90 degree bends The maximum I saw was 0.1 PSI ,add the shorter length of piping on the manifold side of the IC and the throttle body I bet there was no more than 0.25 PSI in the intake piping.

Pressure drop is measured in Kpa, there is a 2.4 Kpa offset on the sensor so you need to deduct 2.4 Kpa from the values.

Original intercooler was a Boost products 600x300 x62.5mm tube and fin IC. After searching around for suitable replacements which would fit I decided on a Treadstone TR1035. This is a slightly smaller version of the IC that Germain has fitted, a little shorter only 11 inches high rather than 12.5 on the bigger TR1235. With 15 rows across the IC as opposed to 17 on the TR1235 about 13% less area to flow through but I am not shooting for 650-700 bhp.

Also the larger TR1235 won't fit on my car with the oil cooler and DSG rad located where they are. The new IC is 90mm thick so substanially thicker than the existing item.

New intercooler is a bar and plate with a turning vane in the end tank to force 50% of the air through the top half of the intercooler.

The old IC is a tube and fin item

New intercooler with the turning vane in the end. Has 3 inch connections on the end as opposed to 2.5 inch on the Boost products item.

Old and new IC together. You can see the old one is a lot thinner.

Intercooler decided upon and ordered it took over 3 weeks to arrive from Turbozentrum in Germany. I had figured out before it arrived how I was going to mount it as I still have the alloy crash bumper which I use to hang the splitter off when that's fitted on track. I remove the number plate on track and there are many holes behind this which feed loads of air to the top of the IC.

Ordered a black 90 degree and 45 degree 63-75mm reducer hose to connect to the existing piping and blue items turned up ?. These had been sent 3 times with the first two being lost apparently, Not having much luck with ordering stuff at the moment.

Intercooler fits with not a not of room left. If I didn't have an oil cooler rad or DSG rad in between the radiator and the IC I could have mounted it further back.

All fitted, took the car for some test runs, immediately the car felt like it picked up quicker and felt a bit more urgent.

The pressure difference has halved and now peaks around 2.4-2.5 PSI. This means the turbo is running slower to deliver the same target boost, typically it's running 5-6K RPM less to make the same boost. I have had to tweak the Intergrator Max tables as the turbo was overboosting on spool but easily sorted.

Cooling performance isn't quite as good as the old IC on the two logs before and after, that was down to the fact that the new IC was shorter than the old one so isn't seeing any airflow at all with the number plate in. I have improvised a scoop to push some air down to the top of the IC and it's a lot better. I am 100% sure when on track with the number plate removed it will be a lot better than than the old IC. The new IC has a plate that diverts 50% of the incoming air to the top of the IC which helps to reduce pressure loss and stops the bottom part of the IC heat soaking.

Took the car for a spin doing some Dragy testing 100-200 Km/h and managed a 7.18s which is about 0.25s faster than my previous best so it's definitely faster. You can even see that in the logs between 110 and 170km/h it's around 0.2s faster.

Last edited:

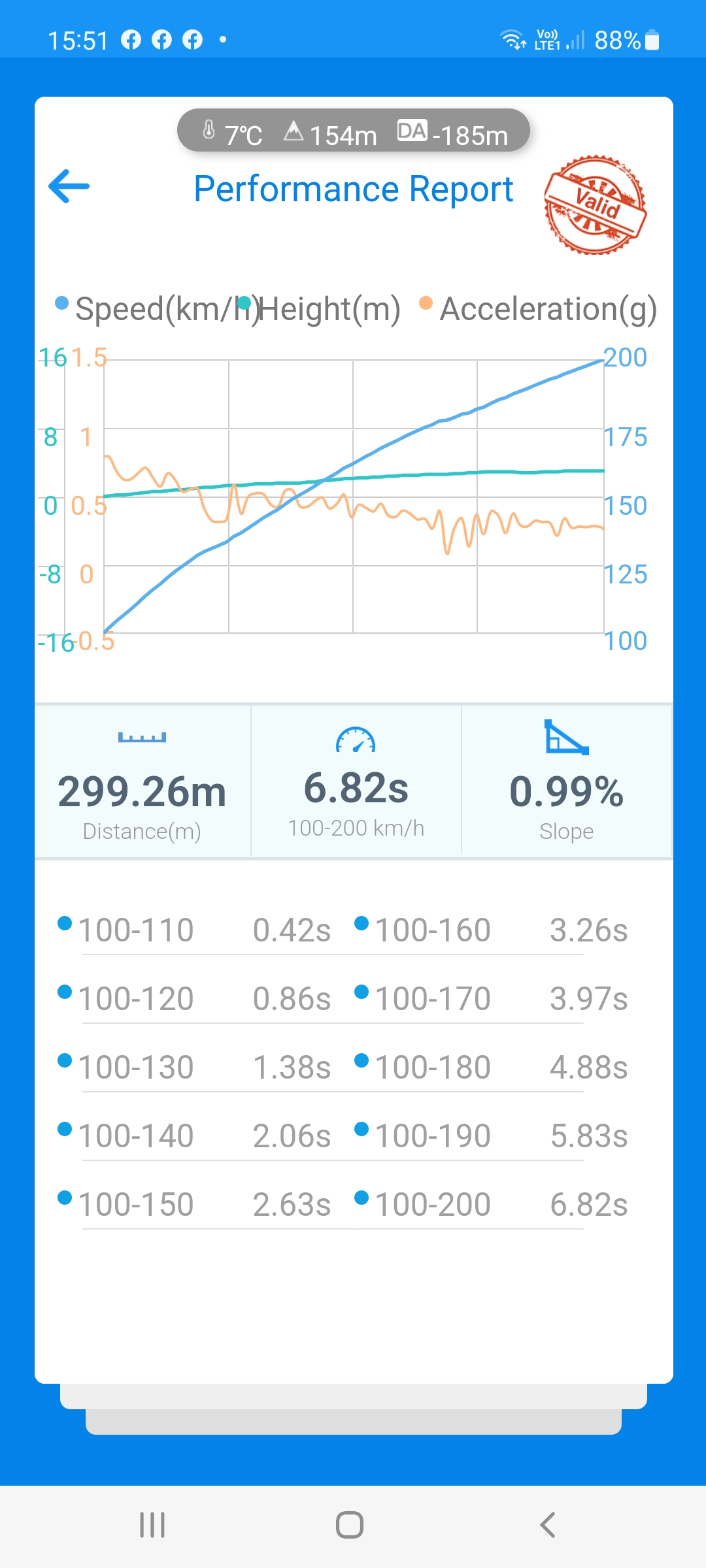

A few days later took the BYC wing off the back of the car to see what effect this has on high speed acceleration. Also popped the front plate in the windscreen to see what the IC will do on track when I goto Bedford on the 21st.

I was impressed cooling was really solid and it managed a 6.82s 100-200 Km/h with 100-160Km/h in 3.26s that's basically 60-100mph .

I was impressed cooling was really solid and it managed a 6.82s 100-200 Km/h with 100-160Km/h in 3.26s that's basically 60-100mph .

Karl that's a very impressive time for 100 to 200 - well done

You measuring emp on this?

You measuring emp on this?

Thanks Bobby, I am not measuring EMP currently would be quite easy to add a sensor and do that.Karl that's a very impressive time for 100 to 200 - well done

You measuring emp on this?

First track day of the year with Opentrack at Bedford Autodrome. Lots of things to be very happy with. The car was very quick in the wetter greasy conditions with my normal road tyres on. I was regularly hitting over 150mph on the 1km straight. Didn't come across anything that the car couldn't pass, Porsche GT3's ,M3's , EVO's ' Lotus Exige, Caterhams etc etc. Coolant, oil and DSG temps all well under control. Think I have the DSG mapping near enough sorted on Ignitron now, DSG oil temps didn't go over around 92 degrees at any point.

Brakes were faultless. Managed to do the fastest lap of the day on my normal road tyres when the track was virtually dry, just the odd wet patch. The tyres were going away at the end of the lap and I crossed the line sideways in a cloud of smoke.

Fitted the AR1's but never managed to find a clear track at any point after that, It always seemed pretty busy when I was out.

Around 14.30 had an issue where the alternator / PAS steering belt threw itself off. Quite scary piling into a corner and turning the wheel only to find the steering is extremely heavy.

Luckily I run the factory undertray and the belt was lying under the engine. Took some finding though. Unluckily the reason it had come off was the 4 bolts securing the pulley had undone. Only one remained, one had sheared off and the other two were missing.

Managed to find two bolts in the engine compartment that I could use. They were attaching the drivers side engine mount support bracket. Installed the bolts so I had 3 bolts securing the pulley and managed to drive home the 90 miles at a sedate 55-60mph.

Surprised I never felt or heard anything before the belt came off.

Why did the bolts come loose?? . They were torqued correctly but didn't have any Loctite on them. I suspect another issue was with the longer belt I fitted with the larger alternator pulley, it may be a little too short still as the alternator tensioner is almost at the end of it's travel on maximum tension.

Going forward I could just replace the existing parts, I have another stock damper pulley but think I may take the opportunity to upgrade to a TFSI fluidampr pulley with a 6 bolt TFSI pulley and get a longer PAS belt.

I need to also sort the PAS pump out to stop the cavitation that is occuring and may be related to the loading on the pulley and why it failed. The pipe I have from the PAS pump to the steering rack has no restrictors fitted .

Some videos.

Earlier on when it was a bit overcast / showery.

https://youtu.be/Xnfs1zXh3Ws

Fastest lap of the day finished off with a spin. Around a 2.48 as I crossed the line sideways/backwards.

https://youtu.be/2iAu6j9X2FM

Playing with a 2014 GT3.

https://youtu.be/-dJVyPM2LfI

The tyres were getting to the end of their life as the shoulders were very worn , sliding sideways at 70mph doesn't help tyre life.

Regularly hitting over 150mph at the end of the straight the intercooler upgrade has certainly helped. Can run 0.2 bar more boost consistently if I want too.

There is always a good selection of cars at Bedford from super cars to normal family cars. This one was being driven particularly hard. I did spot it in the garage later , had more oil on the outside of the engine than in it.

They take good piccies on Opentrack track days.

Easily quicker than several Lotus Exige cars that were there.

The GT3 that was there. Full carbon ceramic brake set up. The BTCC brakes on the front of mine easily matched those.

Spoke to the owner of this car , he came over for a word, very impressed with how fast it was considering it's only a 1.8.

Brakes were faultless. Managed to do the fastest lap of the day on my normal road tyres when the track was virtually dry, just the odd wet patch. The tyres were going away at the end of the lap and I crossed the line sideways in a cloud of smoke.

Fitted the AR1's but never managed to find a clear track at any point after that, It always seemed pretty busy when I was out.

Around 14.30 had an issue where the alternator / PAS steering belt threw itself off. Quite scary piling into a corner and turning the wheel only to find the steering is extremely heavy.

Luckily I run the factory undertray and the belt was lying under the engine. Took some finding though. Unluckily the reason it had come off was the 4 bolts securing the pulley had undone. Only one remained, one had sheared off and the other two were missing.

Managed to find two bolts in the engine compartment that I could use. They were attaching the drivers side engine mount support bracket. Installed the bolts so I had 3 bolts securing the pulley and managed to drive home the 90 miles at a sedate 55-60mph.

Surprised I never felt or heard anything before the belt came off.

Why did the bolts come loose?? . They were torqued correctly but didn't have any Loctite on them. I suspect another issue was with the longer belt I fitted with the larger alternator pulley, it may be a little too short still as the alternator tensioner is almost at the end of it's travel on maximum tension.

Going forward I could just replace the existing parts, I have another stock damper pulley but think I may take the opportunity to upgrade to a TFSI fluidampr pulley with a 6 bolt TFSI pulley and get a longer PAS belt.

I need to also sort the PAS pump out to stop the cavitation that is occuring and may be related to the loading on the pulley and why it failed. The pipe I have from the PAS pump to the steering rack has no restrictors fitted .

Some videos.

Earlier on when it was a bit overcast / showery.

https://youtu.be/Xnfs1zXh3Ws

Fastest lap of the day finished off with a spin. Around a 2.48 as I crossed the line sideways/backwards.

https://youtu.be/2iAu6j9X2FM

Playing with a 2014 GT3.

https://youtu.be/-dJVyPM2LfI

The tyres were getting to the end of their life as the shoulders were very worn , sliding sideways at 70mph doesn't help tyre life.

Regularly hitting over 150mph at the end of the straight the intercooler upgrade has certainly helped. Can run 0.2 bar more boost consistently if I want too.

There is always a good selection of cars at Bedford from super cars to normal family cars. This one was being driven particularly hard. I did spot it in the garage later , had more oil on the outside of the engine than in it.

They take good piccies on Opentrack track days.

Easily quicker than several Lotus Exige cars that were there.

The GT3 that was there. Full carbon ceramic brake set up. The BTCC brakes on the front of mine easily matched those.

Spoke to the owner of this car , he came over for a word, very impressed with how fast it was considering it's only a 1.8.

Sagti

New Member

Wow, super impressed with this whole build! Well done mate.

You have made me change my mind from going ECUmaster - to Ingnitron. I am currently building 2 cars. My daughters (my ex mk4 1.8T) and a 3.2 TT with DSG. Since you have got the ecu working well with the DSG, which was my original reason for going the ECUmaster route, I am thinking Ignitron is made for me. Will be turboing the TT when I am finished the golf.

I have ordered a Pulsar turbo G25-660 with 0.92 AR exhaust housing. Reason for rebuild is my daughter had the timing belt break = 20 bent valves. Took the head off and found the pistons were rocking quite badly, then also noticed the exhaust housing on the K03s was slightly cracked. We then decided an upgrade was on the cards as it won't really cost THAT much more and at least we have achieved something!

Your thread has offered up some much needed inspiration and motivation - Thank you.

When I reach that point I would love to pick on yours and others expertise on the setups.

Incidentally my name is Karl and I am also busy with my 3.0TDi, but mine is in 2007 Q7 guise.

You have made me change my mind from going ECUmaster - to Ingnitron. I am currently building 2 cars. My daughters (my ex mk4 1.8T) and a 3.2 TT with DSG. Since you have got the ecu working well with the DSG, which was my original reason for going the ECUmaster route, I am thinking Ignitron is made for me. Will be turboing the TT when I am finished the golf.

I have ordered a Pulsar turbo G25-660 with 0.92 AR exhaust housing. Reason for rebuild is my daughter had the timing belt break = 20 bent valves. Took the head off and found the pistons were rocking quite badly, then also noticed the exhaust housing on the K03s was slightly cracked. We then decided an upgrade was on the cards as it won't really cost THAT much more and at least we have achieved something!

Your thread has offered up some much needed inspiration and motivation - Thank you.

When I reach that point I would love to pick on yours and others expertise on the setups.

Incidentally my name is Karl and I am also busy with my 3.0TDi, but mine is in 2007 Q7 guise.

Hi Karl,

No problem with you contacting me if you need any help. There is an active Facebook forum for Ignitron users that could be useful to join.

www.facebook.com

Ignitron also works very well for the 3.2 v6 , @<tuffty/> had a 600bhp + 1.8T build using Ignitron that destroyed itself when the IE rod failed on one of the cylinders. He replaced that engine with a 3.2 V6 and is currently running around 500bhp and looking to go DSG at some point in the future.

www.facebook.com

Ignitron also works very well for the 3.2 v6 , @<tuffty/> had a 600bhp + 1.8T build using Ignitron that destroyed itself when the IE rod failed on one of the cylinders. He replaced that engine with a 3.2 V6 and is currently running around 500bhp and looking to go DSG at some point in the future.

There is much reading on his build thread if you have a spare time, a week or two.

www.audi-sport.net

www.audi-sport.net

No problem with you contacting me if you need any help. There is an active Facebook forum for Ignitron users that could be useful to join.

Ignitron ECU users group | Facebook

This group was created primarily for Ignitron ECU users to discuss technical questions (f.eg: setting up the ECU, sharing and analyzing logs, suggestions, bugs, information regarding to the...

www.facebook.com

www.facebook.com

There is much reading on his build thread if you have a spare time, a week or two.

My minor modding thread

Made some progress... had an issue with one of the GSF fans (new at the time of fitting the VR6 in)... I had been getting quite a large vibration from the fan when they were on and turns out that the larger fan was the culprit and the blade assembly had come loose ...so a bit of locktight...

Sagti

New Member

Thank you sir. I will surely read that entire thread.

First job at hand is fitting the turbo and finishing up with my daughters golf. So for now 1.8T stuff. Hoping to get it up to @Prawn Audi level. (Really enjoy watching that on the tube) perhaps a little less as it is a street car. What do you guys think of the 0.92AR exhaust housing, I am a little worried I went too big, but I was thinking of limiting torque down low to save the 02M.

I would like to go the 2L route but struggling to find a crankshaft in South Africa for a reasonable price. So I am thinking of just going with 82mm pistons like this https://www.bar-tek-tuning.com/1-8t-pistons-conrods-set-wiseco-bar-tek. I am also going to build my own turbo manifold but trying to find an exhaust flange / or someone to laser cut one for me is also proving an issue. I am considering cutting up the stock mani and using that as the flange at this point.

I may start my own thread, as I don't want to hijack yours!

First job at hand is fitting the turbo and finishing up with my daughters golf. So for now 1.8T stuff. Hoping to get it up to @Prawn Audi level. (Really enjoy watching that on the tube) perhaps a little less as it is a street car. What do you guys think of the 0.92AR exhaust housing, I am a little worried I went too big, but I was thinking of limiting torque down low to save the 02M.

I would like to go the 2L route but struggling to find a crankshaft in South Africa for a reasonable price. So I am thinking of just going with 82mm pistons like this https://www.bar-tek-tuning.com/1-8t-pistons-conrods-set-wiseco-bar-tek. I am also going to build my own turbo manifold but trying to find an exhaust flange / or someone to laser cut one for me is also proving an issue. I am considering cutting up the stock mani and using that as the flange at this point.

I may start my own thread, as I don't want to hijack yours!

You don't want a 0.92 exhaust housing, The 0.72 is fine . Bill Brockbank at Badger 5 has published dyno graphs of the same engine with a 0.72 AR hotside and 0.92 hotside and the 0.92 doesn't give any benefit at all. If you had a 3L engine instead of a 1.8 a larger hotside may be advisable. One of my mates at work comes from Durban and some of the stories he tells me are a little scary. Certainly interesting car scene out there .Thank you sir. I will surely read that entire thread.

First job at hand is fitting the turbo and finishing up with my daughters golf. So for now 1.8T stuff. Hoping to get it up to @Prawn Audi level. (Really enjoy watching that on the tube) perhaps a little less as it is a street car. What do you guys think of the 0.92AR exhaust housing, I am a little worried I went too big, but I was thinking of limiting torque down low to save the 02M.

I would like to go the 2L route but struggling to find a crankshaft in South Africa for a reasonable price. So I am thinking of just going with 82mm pistons like this https://www.bar-tek-tuning.com/1-8t-pistons-conrods-set-wiseco-bar-tek. I am also going to build my own turbo manifold but trying to find an exhaust flange / or someone to laser cut one for me is also proving an issue. I am considering cutting up the stock mani and using that as the flange at this point.

I may start my own thread, as I don't want to hijack yours!

I follow some SA You tube channels. https://www.youtube.com/c/LorenzoLakay/featured

I had the chance to rebuild my car to a 2.0 when the Wossner pistons gave up but I stuck with 82.5mm pistons to get around 1850cc. Plenty fast enough for me on track and on the road. You need to make some mods to the gearbox to strengthen it, 4th gear support is well worth doing.

As for Bartek they sell lots of stuff, pretty much most of it you can get cheaper elsewhere if you look around. A lot of the stuff they sell is made cheaply in China and sold on at an inflated price. When looking for pistons don't bother with Wossners for the 1.8T. They are not fit for purpose. JE , CP , Supertech, Wiseco are all good.

Sagti

New Member

Damn, thats what I thought, can't seem to find a dyno of a G25-660 AR0.92 but I will keep searching the forum. Unfortunately I will have to run it though as I already have it in hand. I know a lot of guys hate the copies of Garrett, but I have heard good things about Pulsar Turbo, and it looks very nice. No way I could afford the real thing as this C****19 thing has hit me financially and now we seem to be having bigger issues than that even.... Almost sold the TT project car to pay for the repair of the 1.8T, but daughter wouldn't have it  . So hope nobody flames me.

. So hope nobody flames me.

Yeah, I saw your Wossner woes as well as TeamPrawns. I like JE and Wiseco. Where did you pick up yours? Unfortunately over here guys who carry such items are mostly inflating prices beyond a joke, and also moved on to carry only newer model stuff.

I have even considered putting in some nice TFSI pistons and Rods with 23mm small ends I can find over here that are good for 700HP but I think the compression ratio would be way low as the piston compression height is about 3 mm shorter than a set of Wiseco 8.5:1

and I don't think I can skim the head enough to make it workable. Any pointers will be well taken, maybe @badger5 can ship something to me and give me some options.

Agree with you about strengthening the 02M, looking at getting a solid rod insert machined to go inside the intermediate shaft, the 4th gear support brass item, and I am sure I can make those brackets with the threaded rod that goes through the others. May even attempt making the 4th gear support myself also, although shipping on that should not be too bad.

Thank you so much for your feedback, really appreciate your time. Glad I found an old school "forum" that still works, I don't do facebook and all that malarkey. I still remember talking to Badger5 back in like 2005ish on the vortex forums.

I think I will start building the exhaust manifold by cutting the oem one and using it as a flange. If my welding fails I can cut it off at a later date and either make my own out of 12mm steel, or buy one in if I manage to find one. (Problem over here is shipping and duties usually end up costing more than the item!!) The oem casting looks pretty good to weld on, probably a terrible idea, but may be worth a try. I could buy a high flow cast mani and weld up a T3 to Vband adapter but like the idea of a more equal length / better flowing type with a little more flexibility on positioning the turbo.

Yeah, I saw your Wossner woes as well as TeamPrawns. I like JE and Wiseco. Where did you pick up yours? Unfortunately over here guys who carry such items are mostly inflating prices beyond a joke, and also moved on to carry only newer model stuff.

I have even considered putting in some nice TFSI pistons and Rods with 23mm small ends I can find over here that are good for 700HP but I think the compression ratio would be way low as the piston compression height is about 3 mm shorter than a set of Wiseco 8.5:1

and I don't think I can skim the head enough to make it workable. Any pointers will be well taken, maybe @badger5 can ship something to me and give me some options.

Agree with you about strengthening the 02M, looking at getting a solid rod insert machined to go inside the intermediate shaft, the 4th gear support brass item, and I am sure I can make those brackets with the threaded rod that goes through the others. May even attempt making the 4th gear support myself also, although shipping on that should not be too bad.

Thank you so much for your feedback, really appreciate your time. Glad I found an old school "forum" that still works, I don't do facebook and all that malarkey. I still remember talking to Badger5 back in like 2005ish on the vortex forums.

I think I will start building the exhaust manifold by cutting the oem one and using it as a flange. If my welding fails I can cut it off at a later date and either make my own out of 12mm steel, or buy one in if I manage to find one. (Problem over here is shipping and duties usually end up costing more than the item!!) The oem casting looks pretty good to weld on, probably a terrible idea, but may be worth a try. I could buy a high flow cast mani and weld up a T3 to Vband adapter but like the idea of a more equal length / better flowing type with a little more flexibility on positioning the turbo.

I got my JE pistons from Bill. Here is a link to the test Bill did with different turbine housings. The larger turbine housing just resulted in a slower boost response so effectively more lag. I have heard a few stories about Pulsar G25 turbos. Don't expect exactly the same performance as a genuine item.

I wouldn't try welding to a cast flange on a stock exhaust manifold. Do they have any of the 1.8 Normally Aspirated models over there. They are normally 125bhp and use the same cylinder head as the turbo cars but the exhaust manifolds are a welded tube affair. If you could find one of these you could use the flange as a basis to make your own exhaust manifold.

https://www.proxyparts.com/car-part...53031aa/part/exhaust-manifold/partid/1297955/

I wouldn't try welding to a cast flange on a stock exhaust manifold. Do they have any of the 1.8 Normally Aspirated models over there. They are normally 125bhp and use the same cylinder head as the turbo cars but the exhaust manifolds are a welded tube affair. If you could find one of these you could use the flange as a basis to make your own exhaust manifold.

https://www.proxyparts.com/car-part...53031aa/part/exhaust-manifold/partid/1297955/

Sagti

New Member

Thank you, very good info - I will try and find one of those manifolds! I also thought about it a bit more and agree with you - if I can't get hold of the NA exhaust manifold, I will buy a scrap piece of 12mm steel and make a mild steel flange by hand. I'd rather just take some more time and do it right the first time.

Yeah, not expecting the Pulsar to be equal to the Garrett at all. But for the money it seems very good.

That graph shows I for sure should have gone with the 0.72AR. I wonder if those 3 dyno runs were on the same tune? If it proves really bad, I will order the 0.72 from them and swap it out. Either that or try harder to find a 2.0 crank, as I am sure that will spool it much better.

Yeah, not expecting the Pulsar to be equal to the Garrett at all. But for the money it seems very good.

That graph shows I for sure should have gone with the 0.72AR. I wonder if those 3 dyno runs were on the same tune? If it proves really bad, I will order the 0.72 from them and swap it out. Either that or try harder to find a 2.0 crank, as I am sure that will spool it much better.

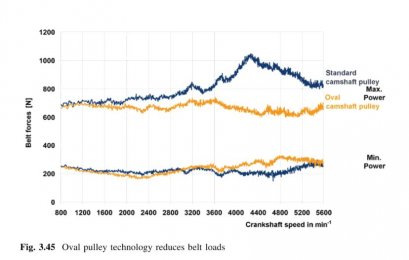

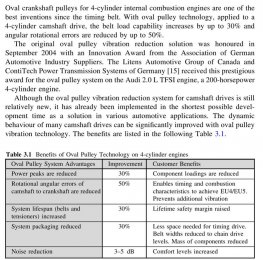

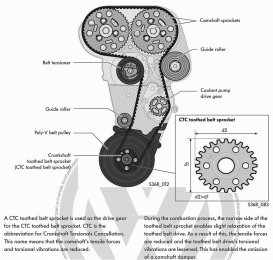

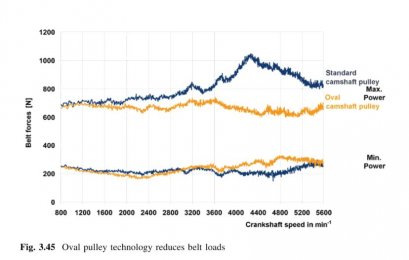

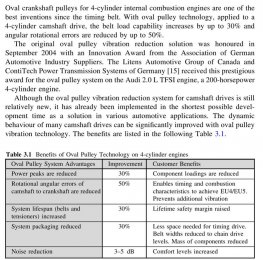

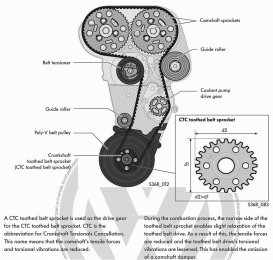

Another long post and another small upgrade for my 1.8T engine after I had an issue with it on the last trackday. The bolts on the stock crankshaft damper came loose and threw the alternator/ PAS belt off. Only one bolt remained finger tight with one sheared off and two missing. I hadn't threadlocked them which may have resulted in their loosening. Decided to go with a Fluidampr as an upgrade and also as the stock 4 bolt cam belt drive sprocket was damaged so swapped to the EA113 2.0 TFSI 6 bolt sprocket. There are several independent dyno tests of the Fluidampr pulleys replacing stock or lightened pulleys and they actually make more power than stock or lightened pulleys, so another small improvement in power as well as a more reliable, smoother running engine. Figured that Audi had recognised that maybe 4 bolts were not good enough on the 1.8T. The sprockets are a direct swap and apart from getting 6 bolt fixing for the Fluidampr you also get around a 30% reduction in maximum cambelt loading. The stock 1.8T engine had a 60K mile change interval, The EA113 2.0 engine was 100K with no belt damper as well. The reason they managed to do this is the cam sprocket is oval ???. A video of the genuine sprocket I purchased.

This innovation won Litens and Continental an award for engineering innovation and a lot of cars these days use oval or tri oval sprockets on belts to reduce belt loading and make them run quieter. I could only find the 6 bolt sprocket available as a genuine item OE made by Litens, I suspect the item is patented so this may make it difficult for others to copy it. Fortunately not too expensive from AKS Tuning where I ordered all the parts from. They are a registered seller for Fluidampr in the UK.

Fluidampr Engine Damper - 2.0 TFSI - 551211

The timing marks on the damper are in the same place so not an issue there. I used the stock diamond washer and stock M16 bolt to fit the belt sprocket, This is what I have always used and not had any issues but then I only rev the engine to 7800rpm tops. I bought some M8 X 20 12.9 cap head screws to secure the pulley and used Nordlock washers along with threadlock. The stock bolts are 16mm long and with the thicker flange on the Fluidampr and Noordlock washers longer bolts at 20mm are needed. I always like to try and measure improvements with this change the engine idles smoother and definitely seems to run smoother, it just feels less coarse. I wondered If I could see anything on the logs and looking at the RPM traces on logs I can definitely see that the trace for crank RPM is smoother.

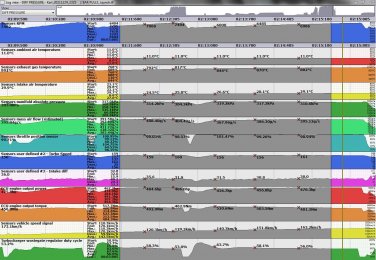

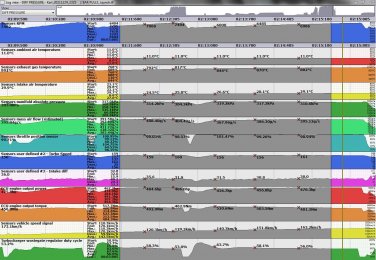

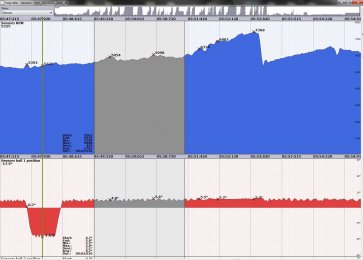

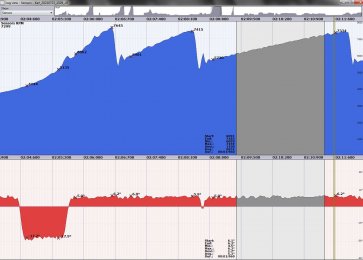

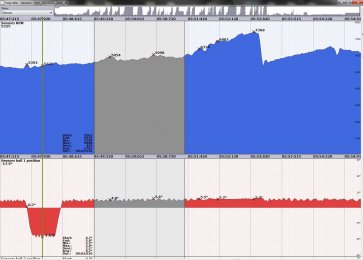

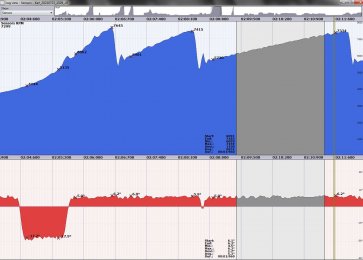

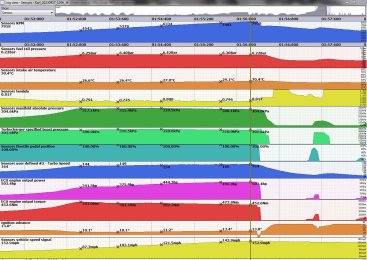

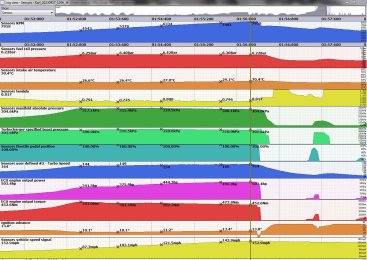

I was actually logging the engine when the belt came off so bolts were loose. Screenshot of the crank RPM signal with loose bolts, looks like a plowed field.

One from several months ago typical of what I have always seen with the stock damper.

And one from several logging runs I have made with the Fluidampr. There is a noticeable reduction in "noise" on the crank signal.

Also a few screenshots from some of the research papers I found on oval crank sprockets and how they reduce belt loads, increase belt life and reduce noise.

How an oval pulley reduces belt loads.

This innovation won Litens and Continental an award for engineering innovation and a lot of cars these days use oval or tri oval sprockets on belts to reduce belt loading and make them run quieter. I could only find the 6 bolt sprocket available as a genuine item OE made by Litens, I suspect the item is patented so this may make it difficult for others to copy it. Fortunately not too expensive from AKS Tuning where I ordered all the parts from. They are a registered seller for Fluidampr in the UK.

Fluidampr Engine Damper - 2.0 TFSI - 551211

The timing marks on the damper are in the same place so not an issue there. I used the stock diamond washer and stock M16 bolt to fit the belt sprocket, This is what I have always used and not had any issues but then I only rev the engine to 7800rpm tops. I bought some M8 X 20 12.9 cap head screws to secure the pulley and used Nordlock washers along with threadlock. The stock bolts are 16mm long and with the thicker flange on the Fluidampr and Noordlock washers longer bolts at 20mm are needed. I always like to try and measure improvements with this change the engine idles smoother and definitely seems to run smoother, it just feels less coarse. I wondered If I could see anything on the logs and looking at the RPM traces on logs I can definitely see that the trace for crank RPM is smoother.

I was actually logging the engine when the belt came off so bolts were loose. Screenshot of the crank RPM signal with loose bolts, looks like a plowed field.

One from several months ago typical of what I have always seen with the stock damper.

And one from several logging runs I have made with the Fluidampr. There is a noticeable reduction in "noise" on the crank signal.

Also a few screenshots from some of the research papers I found on oval crank sprockets and how they reduce belt loads, increase belt life and reduce noise.

How an oval pulley reduces belt loads.

Last edited:

Sagti

New Member

Very interesting. Great info. Who would have thought an oval shape would be better - very counter intuitive.

Who would have thunk! Nice write up Karl.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

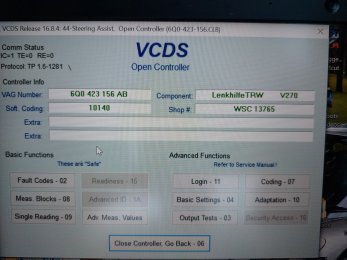

Haven't updated the thread for a while. Been too busy doing other things . Some of them to the TT. I did this mod with the power steering pump back in June.

Small upgrade to the car to try and resolve issues with the power steering on track. Getting lots of noise from the power steering I think due to cavitation in the pump and the fluid getting aerated / hot. I have a decent size cooler but with the power steering pump pulley being 20% smaller than the crank pulley the power steering is being spun at 9K RPM when the engine is at 7500 RPM.

Decided to try and install an electric power steering pump, I wanted to keep the existing rack and didn't fancy an electric column assist like the Corsa rack mod.

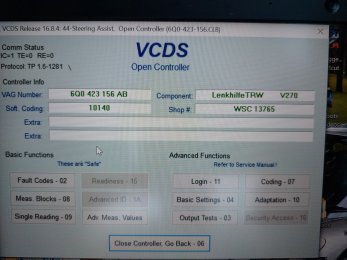

I found that Porsche cup cars used an electric power steering pump made by TRW that was almost identical to some model Astras. Ford and Volvo also used similar pumps , and of course there are pumps used in the Polo, Fabia , Ibiza and Audi A1.

The Astra, Ford, Volvo and a few other types are all usually used in a fairly dumb manner where the pump just responds to load and cannot actually see any sensors on the car.

The VAG pump is intelligent, it sees the engine RPM, Vechicle speed and steering wheel position over the CAN bus from the ECU, ABS module and steering wheel sensor for the ESP.

It only has 5 wires to connect, ground, 12V battery through 50A fuse, Ignition switched 12V and a CANH , CANL .

The pump doesn't actually start running till the engine is running that's why it needs the RPM signal. The assist is speed dependent as it knows how fast the car is going, and from the signal it gets from the steering wheel ESP sensor it knows when and how fast the steering wheel is being turned.

I bought a cheap used pump off a Skoda Fabia for £40 just to see if I could fit it and make it work. It does fit and I think works pretty well. Had to modify the bracket slightly and fitted the pump in a very similar place to the OE location under the LHS headlight, behind the bumper. It only just fits but I managed to reinstall the wheel arch liner so you can't see it and there is plenty of room so the tyre does not foul the liner.

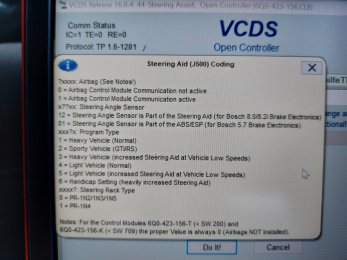

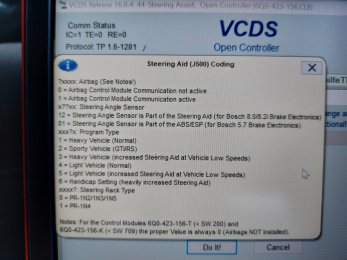

There are several maps for varying assistance from disabilty mode which is very light through too a light vechicle which is not so much assistance. I have found option 2 or 5 seem to be the best in terms of feel and assistance.

Had to recode the module to 012 for the first three digits to get rid of the air bag fault code and make the pump use the ESP sensor. Last two digits of the code determine the map. There are also other maps not shown on VCDS 7, 8 and 9 all work as well.

Adding the electric pump has added around 0.5Kg weight to the car but moved 5Kg from the RHS of the engine to the gearbox side so slightly improved weight balance. The pump can take upto 65A current if you run it at the rack stops , It is rated to 100Bar (1470 PSI) but typically take around 3A when driving in a straight line and 10-20A if you are moving the steering wheel quickly at speed.

AN6 fittings from Torques on Fleabay, Pump outlet is an M16 I used the original green washer that came with the pump. Used just over 1m of braided teflon pipe. Braided pipe 2500PSI normal working pressure, burst pressure of 10,000 PSI so easily handles the 100Bar from the power steering pump.

Weight of the alternator mount bracket after I cut the surplus off and removed the pump, reservoir and pipe between the pump and reservoir.

Pump fitted under the LHS headlight. You have to remove the bumper and headlight to top up the level. On the stock Fabia, Polo etc you need to remove the battery to top up the fluid. You can see the level on the side of the bottle .

size comparison of pump

Weight of complete mounting bracket, pump and reservoir.

weight of the new pump on it's own

TT has a spare 50A fuse way already.

Small upgrade to the car to try and resolve issues with the power steering on track. Getting lots of noise from the power steering I think due to cavitation in the pump and the fluid getting aerated / hot. I have a decent size cooler but with the power steering pump pulley being 20% smaller than the crank pulley the power steering is being spun at 9K RPM when the engine is at 7500 RPM.

Decided to try and install an electric power steering pump, I wanted to keep the existing rack and didn't fancy an electric column assist like the Corsa rack mod.

I found that Porsche cup cars used an electric power steering pump made by TRW that was almost identical to some model Astras. Ford and Volvo also used similar pumps , and of course there are pumps used in the Polo, Fabia , Ibiza and Audi A1.

The Astra, Ford, Volvo and a few other types are all usually used in a fairly dumb manner where the pump just responds to load and cannot actually see any sensors on the car.

The VAG pump is intelligent, it sees the engine RPM, Vechicle speed and steering wheel position over the CAN bus from the ECU, ABS module and steering wheel sensor for the ESP.

It only has 5 wires to connect, ground, 12V battery through 50A fuse, Ignition switched 12V and a CANH , CANL .

The pump doesn't actually start running till the engine is running that's why it needs the RPM signal. The assist is speed dependent as it knows how fast the car is going, and from the signal it gets from the steering wheel ESP sensor it knows when and how fast the steering wheel is being turned.

I bought a cheap used pump off a Skoda Fabia for £40 just to see if I could fit it and make it work. It does fit and I think works pretty well. Had to modify the bracket slightly and fitted the pump in a very similar place to the OE location under the LHS headlight, behind the bumper. It only just fits but I managed to reinstall the wheel arch liner so you can't see it and there is plenty of room so the tyre does not foul the liner.

There are several maps for varying assistance from disabilty mode which is very light through too a light vechicle which is not so much assistance. I have found option 2 or 5 seem to be the best in terms of feel and assistance.

Had to recode the module to 012 for the first three digits to get rid of the air bag fault code and make the pump use the ESP sensor. Last two digits of the code determine the map. There are also other maps not shown on VCDS 7, 8 and 9 all work as well.

Adding the electric pump has added around 0.5Kg weight to the car but moved 5Kg from the RHS of the engine to the gearbox side so slightly improved weight balance. The pump can take upto 65A current if you run it at the rack stops , It is rated to 100Bar (1470 PSI) but typically take around 3A when driving in a straight line and 10-20A if you are moving the steering wheel quickly at speed.

AN6 fittings from Torques on Fleabay, Pump outlet is an M16 I used the original green washer that came with the pump. Used just over 1m of braided teflon pipe. Braided pipe 2500PSI normal working pressure, burst pressure of 10,000 PSI so easily handles the 100Bar from the power steering pump.

Weight of the alternator mount bracket after I cut the surplus off and removed the pump, reservoir and pipe between the pump and reservoir.

Pump fitted under the LHS headlight. You have to remove the bumper and headlight to top up the level. On the stock Fabia, Polo etc you need to remove the battery to top up the fluid. You can see the level on the side of the bottle .

size comparison of pump

Weight of complete mounting bracket, pump and reservoir.

weight of the new pump on it's own

TT has a spare 50A fuse way already.

Anybody interested in doing this These are the parts I ordered to make up the high pressure line to the rack. I would buy a pump with a cage and wiring attached.

https://www.ebay.co.uk/itm/380711703154 I ordered 2M and the line I made up was 1.1M long

https://www.ebay.co.uk/itm/360709155769 16mm x 1.5 power steering fitting to AN6

https://www.ebay.co.uk/itm/171780202270 AN6 14mm banjo fitting

https://www.ebay.co.uk/itm/160764021291 AN6 90 degree fitting

https://www.ebay.co.uk/itm/171314533959 AN6 straight fitting

The pump was a offA 2004 Skoda Fabia 6Q0423156AB

I believe that pretty much any pump will work in the TT although I couldn't guarantee it. The reason I went with this pump is because it is shown as compatible with the 1.8T polo GTI .

Map options on this pump. I have tried them all and ended up where I thought I would at map 2. This has good assistance when moving slowly but drops when on the move.

I logged the current taken by the pump on VCDS when driving the car. On the measuring blocks there are several blocks including current take by the pump. I have been running this on the car over a month now with no issues. If you think that it is fitted on small engine cars with small 90A alternators and works fine on those cars then it's not an issue on the TT.

https://www.ebay.co.uk/itm/380711703154 I ordered 2M and the line I made up was 1.1M long

https://www.ebay.co.uk/itm/360709155769 16mm x 1.5 power steering fitting to AN6

https://www.ebay.co.uk/itm/171780202270 AN6 14mm banjo fitting

https://www.ebay.co.uk/itm/160764021291 AN6 90 degree fitting

https://www.ebay.co.uk/itm/171314533959 AN6 straight fitting

The pump was a offA 2004 Skoda Fabia 6Q0423156AB

I believe that pretty much any pump will work in the TT although I couldn't guarantee it. The reason I went with this pump is because it is shown as compatible with the 1.8T polo GTI .

Map options on this pump. I have tried them all and ended up where I thought I would at map 2. This has good assistance when moving slowly but drops when on the move.

I logged the current taken by the pump on VCDS when driving the car. On the measuring blocks there are several blocks including current take by the pump. I have been running this on the car over a month now with no issues. If you think that it is fitted on small engine cars with small 90A alternators and works fine on those cars then it's not an issue on the TT.

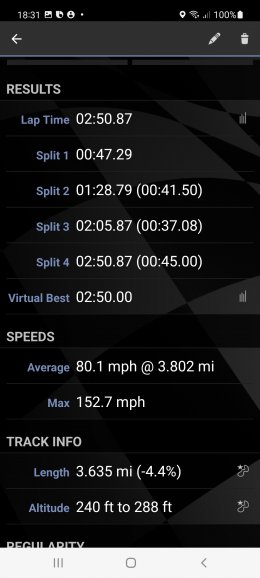

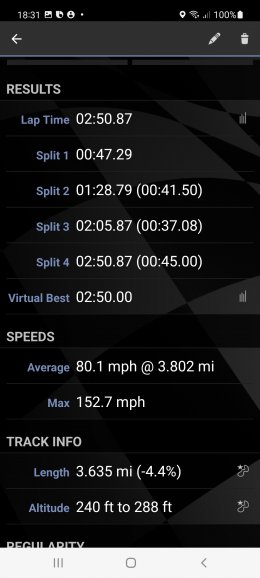

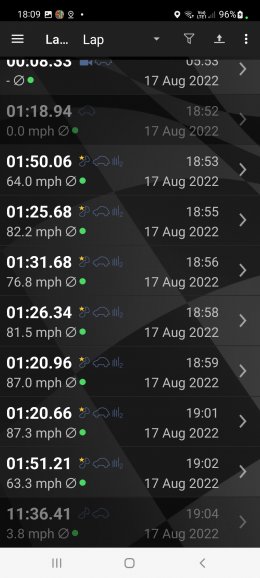

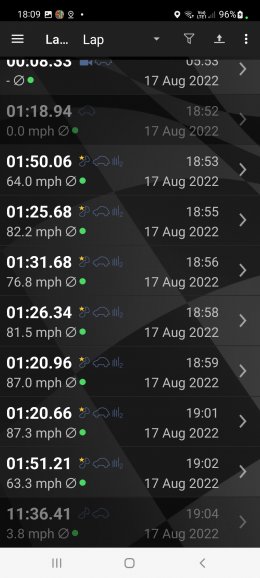

First Evening track day at Donnington on the 17th went quite well. First time out on track with the new Electric power steering pump and it worked faultlessly, No horrible whining after a few laps. Really good weighting. Quite a few red flag periods due to cars breaking down or burying themselves in the gravel. This seems to be an issue with Donnington as people seem to run out of talent down Craners or try and carry too much speed through Redgate. Probably won't do an evening session again because of this. Had a passenger in for all the laps I did, My mate Phil Derbyshire is a biker and used to race as a passenger in a sidecar , He's done plenty of track days himself on bikes. Once I had dialled in the tyre pressures and tweaked a few things that were causing the car to go into limp mode I could try and set some fast laps. Managed a 120.66 and 120.96 with Phil in the car and only running on map 3 at 1.8 bar. A lot faster than I have run before so was pleased with that, Didn't use the push to pass top map. I was going to go back out solo and use the top map and think I could manage a low 1.19. I am losing quite a lot of time in the minimum corner speed's I carry through corners. Unfortunately whilst checking the tyre pressures and wheel nut tightness discovered the NSF outer CV joint boot had pulled off the joint and sprayed grease everywhere. I think the issue is the boots are thermoplastic items which are very good normally but with all the heat the BTCC brakes put out the hub gets very hot. Excellent photos taken by Opentrack as per usual, Got no useable video out of my Nextbase video camera as I had changed the settings to auto record and save when it detected high G forces as the camera has been on my wifes car. So it basically kept thinking I was crashing every time I braked hard. The Go-Pro I setup wrong so was well over exposed. Spent some time with a video editor and did my best to get some footage from it . Just need to sort this CV boot issue as it is a fairly reoccuring one, seems only on the passenger side as that's the shortest shaft with the most articulation .

You tube video of the two fastest laps.

You tube video of the two fastest laps.

Last edited:

Few more pictures from Donnington.Couldn't believe this Nissan Micra with a big car trailer on the back. Had a look and this Micra can tow 500Kg unbraked or 800Kg Braked. The trailer alone is probably 5-600Kg .

And I was sent a link with a picture of the car it was towing. A Lotus.

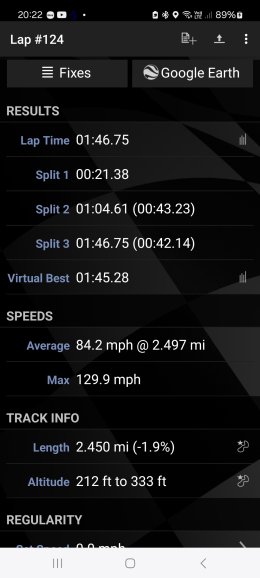

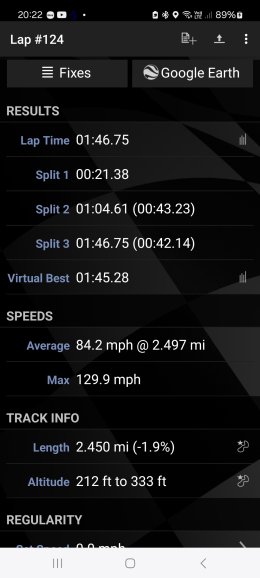

Some lap time info from the fast laps. Couldn't go fast earlier on in the session as there were too many slow cars, M3's Porsche 911's etc getting in the way.

Average speed is 87mph and was hitting around 130mph on the run down past the old museum. Only running 1.8 bar on map 3 so around 460bhp .

And I was sent a link with a picture of the car it was towing. A Lotus.

Some lap time info from the fast laps. Couldn't go fast earlier on in the session as there were too many slow cars, M3's Porsche 911's etc getting in the way.

Average speed is 87mph and was hitting around 130mph on the run down past the old museum. Only running 1.8 bar on map 3 so around 460bhp .

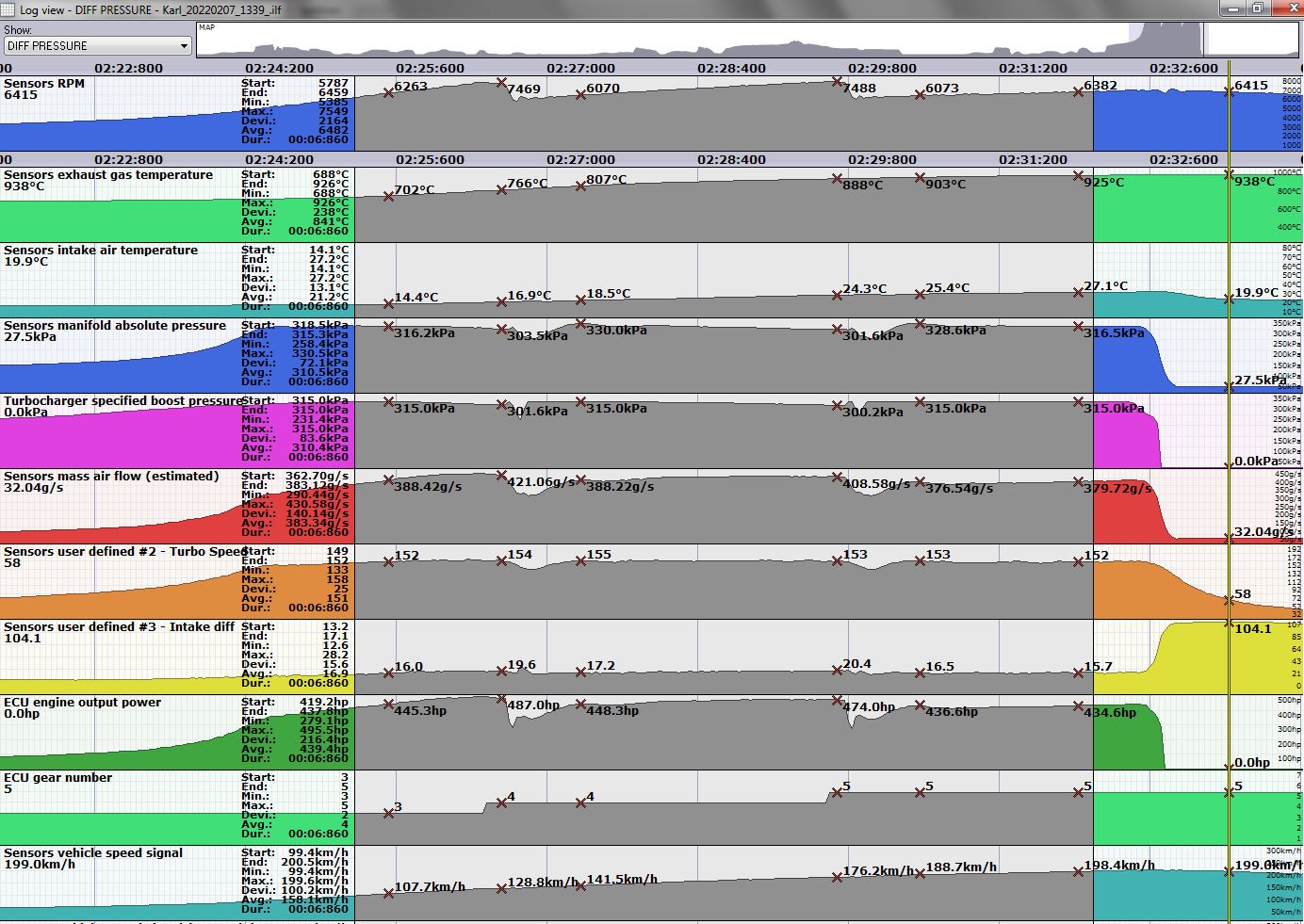

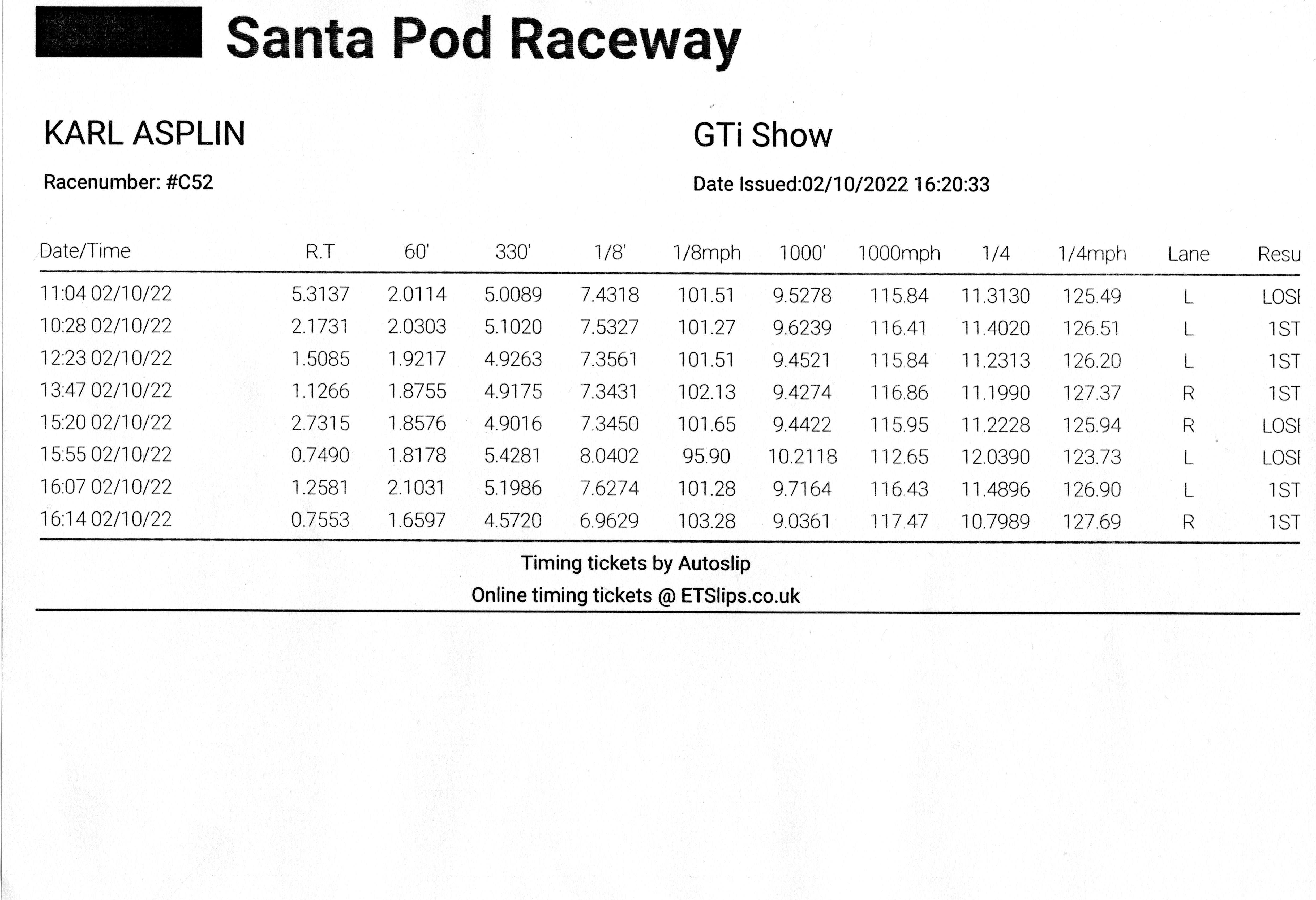

Had a trip to the GTI Festival at Santa Pod on Sunday. Wanted to see if I could get it in the 10's. After quite a few low 11 second runs finally managed to tweak the launch control RPM and settings along with the tyre pressures to get a decent launch and a 10.80 second pass was completed. The car wasn't built for drag racing so 2.5 degrees of camber on the front and 1.5 on the back doesn't help the launch. Used my normal MPSS road tyres as I don't think my Nankang AR1's would have got me any faster.

Did make some adjustments to the car by removing the BYC rear wing, would have looked well out of place with that on.

The APG small port head the car has on it doesn't help power at the top end and I might finally get around to putting the AGU large port head I have on it and see if that makes much difference.

Probably be able to run less boost to make the same power which will help IAT's and allow more timing. I was running the water cooling .

Uploaded some videos to You Tube.

An outside view

https://youtu.be/OIVaLghvCZM

The inside view, No frantic arm twirling or gear stick mashing. DSG gearbox for the easy life

.

.

https://youtu.be/hfMvK0Wdspg

Found a video that somebody else had posted on You tube that shows a view of one of the runs from the stands. Interesting the limited amount of front end lift compared to a lot of cars, probably due to the much stiffer suspension. Also not as loud as it sounds in the car, compared to a lot of other cars anyway.

Used my Dragy and found the times on this to be very accurate compared to the timeslips, usually within 0.05 seconds and 0.5 mph or less.

Official timeslip.

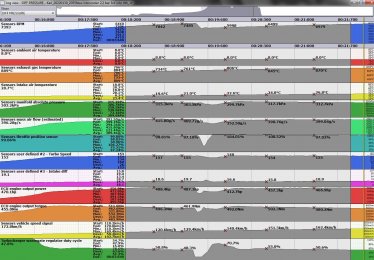

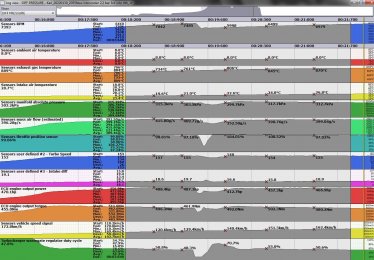

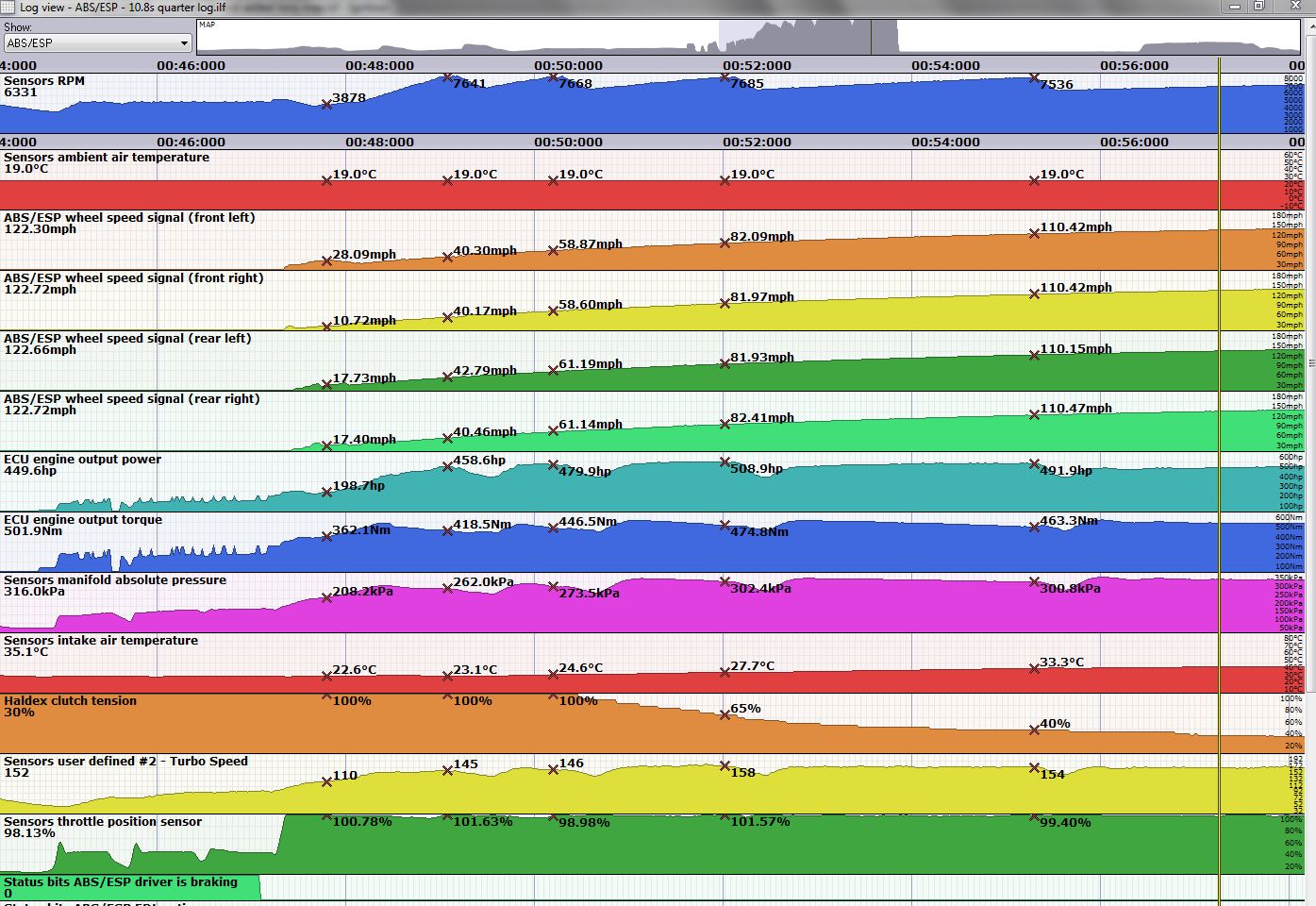

This was part of the log from the fastest run. What happens in the first 60ft makes so much difference to the time you run. Manufacturers of modern high performance cars spend a lot of time calibrating the launch control strategy to get a really quick launch. I can do much of the same with Ignitron and eventually managed to dial in the right launch RPM, with the right amount of throttle and boost. And then using boost by gear limit the power and torque until the speed builds.

Took off the BYC big wing, would have looked daft turning up with that on.

Did make some adjustments to the car by removing the BYC rear wing, would have looked well out of place with that on.

The APG small port head the car has on it doesn't help power at the top end and I might finally get around to putting the AGU large port head I have on it and see if that makes much difference.

Probably be able to run less boost to make the same power which will help IAT's and allow more timing. I was running the water cooling .

Uploaded some videos to You Tube.

An outside view

https://youtu.be/OIVaLghvCZM

The inside view, No frantic arm twirling or gear stick mashing. DSG gearbox for the easy life

https://youtu.be/hfMvK0Wdspg

Found a video that somebody else had posted on You tube that shows a view of one of the runs from the stands. Interesting the limited amount of front end lift compared to a lot of cars, probably due to the much stiffer suspension. Also not as loud as it sounds in the car, compared to a lot of other cars anyway.

Used my Dragy and found the times on this to be very accurate compared to the timeslips, usually within 0.05 seconds and 0.5 mph or less.

Official timeslip.

This was part of the log from the fastest run. What happens in the first 60ft makes so much difference to the time you run. Manufacturers of modern high performance cars spend a lot of time calibrating the launch control strategy to get a really quick launch. I can do much of the same with Ignitron and eventually managed to dial in the right launch RPM, with the right amount of throttle and boost. And then using boost by gear limit the power and torque until the speed builds.

Took off the BYC big wing, would have looked daft turning up with that on.

A better video of the last trackday I did at Donnington . Fastest lap I have done at Donnington.With a Passenger in the car and not running the top map on the engine .

Yes if you look at the photo of the car a few posts up at Santa Pod I had them on. I am very happy with them, used them on track and the road. They are a strong lightweight wheel and the paint finish and quality is good.Do you still have the autec wizard on your car? Are you satisfied ?

Well haven't updated the thread for a while.The TT lives on and is still doing track days and driving on the road despite a few hiccups.

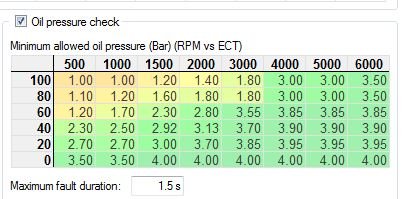

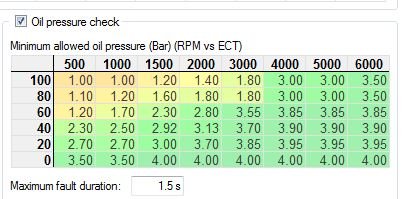

What does Ignitron do that a stock ME7.X ECU doesn't do. It saves your engine from complete failure by spotting issues and making you aware there may be a problem. I probably would not have known there was an issue with the engine till it went bang if it had a stock ECU.

I did a sprint event at Curbrough back in May and had a couple of limp mode events related to low oil pressure at high rpm. The track is a small sprint track with a lot of short straights and tight corners. A run only lasted about a minute. Thought that oil surge may be the issue as oil pressure was dropping below 3 bar at over 4 K . I increased the fault time to 1.5s from 1s and this helped a bit. I then tweaked the value down to 2.8 bar after it limped once more .

The oil pressure at idle, was fine, revving the engine stationary it was fine. The stock oil pressure monitoring system had done nothing.

After hooning the car around all day came to drive it home and was able to monitor the oil pressure at steady speeds and loads . I noticed that under high load the oil pressure would drop below 3 bar as soon as you lifted off the accelerator oil pressure would increase.So took it easy and drove home.

There was no extra engine noise or any other signs there may have been an issue but it wasn't right. After making checks to the oil pressure sensor, oil level etc I pulled the sump off.

Really quite surprised to see that there were cracks on the main caps of 2,3 and 4 . The crank was only being held in by 1 and 5 and under load the cracks had been opening up and letting oil bleed out reducing the pressure. Why these occurred I am not sure, possibly related to the number of times I have launched the car with DSG as I was using it quite a bit that day. 500bhp and 400Lb/ft of torque will brake stuff eventually.

The crank was bent as well which I found out when I removed the engine and took it apart. Really surprised it hadn't spun a shell. You could tell looking at the marking on the shells that it had failed on 2 first then 3 and finally 4. I had previously bought an AGU complete engine and block to use the head so took the opportunity to rebuild the engine with the AGU head and used the AGU crank.

Got some IE billet caps from Badger 5 Ltd and used a company recommended by Badger 5, KMB Engineering Ltd to machine them.

Not the cheapest solution but probably the best long term fix.

All back together and running well now.

The cracked main caps

The repaired block with IE billet caps and TFSI main bolts again.

The oil pressure protection map I use on Ignitron.

What does Ignitron do that a stock ME7.X ECU doesn't do. It saves your engine from complete failure by spotting issues and making you aware there may be a problem. I probably would not have known there was an issue with the engine till it went bang if it had a stock ECU.

I did a sprint event at Curbrough back in May and had a couple of limp mode events related to low oil pressure at high rpm. The track is a small sprint track with a lot of short straights and tight corners. A run only lasted about a minute. Thought that oil surge may be the issue as oil pressure was dropping below 3 bar at over 4 K . I increased the fault time to 1.5s from 1s and this helped a bit. I then tweaked the value down to 2.8 bar after it limped once more .

The oil pressure at idle, was fine, revving the engine stationary it was fine. The stock oil pressure monitoring system had done nothing.

After hooning the car around all day came to drive it home and was able to monitor the oil pressure at steady speeds and loads . I noticed that under high load the oil pressure would drop below 3 bar as soon as you lifted off the accelerator oil pressure would increase.So took it easy and drove home.

There was no extra engine noise or any other signs there may have been an issue but it wasn't right. After making checks to the oil pressure sensor, oil level etc I pulled the sump off.

Really quite surprised to see that there were cracks on the main caps of 2,3 and 4 . The crank was only being held in by 1 and 5 and under load the cracks had been opening up and letting oil bleed out reducing the pressure. Why these occurred I am not sure, possibly related to the number of times I have launched the car with DSG as I was using it quite a bit that day. 500bhp and 400Lb/ft of torque will brake stuff eventually.

The crank was bent as well which I found out when I removed the engine and took it apart. Really surprised it hadn't spun a shell. You could tell looking at the marking on the shells that it had failed on 2 first then 3 and finally 4. I had previously bought an AGU complete engine and block to use the head so took the opportunity to rebuild the engine with the AGU head and used the AGU crank.

Got some IE billet caps from Badger 5 Ltd and used a company recommended by Badger 5, KMB Engineering Ltd to machine them.

Not the cheapest solution but probably the best long term fix.

All back together and running well now.

The cracked main caps

The repaired block with IE billet caps and TFSI main bolts again.

The oil pressure protection map I use on Ignitron.

Attended a Charity Dyno Day at RTEC in Nuneaton on 17th September to see what the engine was making after it's rebuild.

Only issue with the RTEC dyno is it's just FWD and my car has 2.5 degrees of camber on the front tyres which makes getting all the power down at the front a bit tricky.

It was only £40 and for charity and Nick did 45 cars in the day alternating between dynos, so it was a bit of a rush but I was happy. Just looking at the dyno print out you can see that the throttle looks like it's lifted around 7400 rpm. Looking at the logs on Ignitron the throttle was lifted around 7900 just at it got into the limiter.

So looks to me like there was some wheel spinning going on with the dyno. Anyway it made just under 500bhp it was quite warm in there at 25 degrees.

The calculated power and torque from Ignitron was reasonably close to what the dyno says .

View: https://youtube.com/shorts/512p891wY6w

Only issue with the RTEC dyno is it's just FWD and my car has 2.5 degrees of camber on the front tyres which makes getting all the power down at the front a bit tricky.

It was only £40 and for charity and Nick did 45 cars in the day alternating between dynos, so it was a bit of a rush but I was happy. Just looking at the dyno print out you can see that the throttle looks like it's lifted around 7400 rpm. Looking at the logs on Ignitron the throttle was lifted around 7900 just at it got into the limiter.

So looks to me like there was some wheel spinning going on with the dyno. Anyway it made just under 500bhp it was quite warm in there at 25 degrees.

The calculated power and torque from Ignitron was reasonably close to what the dyno says .

View: https://youtube.com/shorts/512p891wY6w

Did a track day on Monday at Donningon on the GP circuit. Always done the National one before so that was a new experience, also first time out with Slick tyres, which was also an experience. Only around 9 or 10 degrees C temperature so the tyres weren't getting that hot. First time out on slicks did around 1.5 laps before I managed to spin the car at the Foggarty Esses right in front of an M3 I had just overtaken. This is when I discovered that slick tyres need a bit more warming up than AR1's. Russel Lloyd and Joe JoJo Tang came along and gave them a passenger ride which was brave of them. Car was running well and I was getting used to the slicks and the extra grip, I have never seen 1.2-1.3G on my phones G meter before on Harrys. Was hoping to try and do some faster laps with just me in the car using the top boost map on the straights to see what kind of time I could do. The virtual best lap was a 1.48.4 and I think something like a 1.46 was possible carrying more speed into the corners and braking a little later . Around 14.30 had an issue with the brakes. I had been hearing the odd metallic rubbing noise on the last 2 or three runs but couldn't pin it down. I was going down to the Melbourne loop around 110mph when I went to brake the pedal went long , car still stopped Ok but wasn't right. As I had done several fast laps thought it might be the brakes being too hot so drove slowly for half a lap and tested the brakes again and they weren't right pedal went nearly to the floor. In the garage didn't take long to find the issue the puddle of break fluid by the passenger side rear wheel was a giveaway. The flexi hose had been touching the very hot brake disc and had melted/ chafed through . I don't have the metal splash shields on the rear and I have different calipers than stock so the hose has more movement than stock. Never been an issue before but I think the extra cornering loads from the slick tyres caused the issue. Will be securing the new brake hose so this cannot happen again. The brake fluid level had dropped to the minimum and had to drive the car home so topped up the reservoir and clamped the rear flexi hose with a Mole grip, and drove home with my rear gunner Russel Lloyd. Fastest lap , The speed doesn't seem to sync very well as it was using the phones 1Hz GPS. Instead of the 10Hz GPS it normally gets from the Garmin Glo.

View: https://youtu.be/OxHlUwwbIkY

View: https://youtu.be/HFEVAmNF55o

The codge to drive the car home

Flexi with a hole in it,

Ooh think I have found the problem

View: https://youtu.be/OxHlUwwbIkY

View: https://youtu.be/HFEVAmNF55o

The codge to drive the car home

Flexi with a hole in it,

Ooh think I have found the problem

First track day of the year at Castle Donington on Monday 28th Feb. Always a bit of a risk this time of the year but weather turned out pretty good. Just some light rain in the afternoon for a while made it interesting on the slicks.Usual issues with quite a few track closures due to people getting stuck in the gravel or even on the wet muddy grass. If you look on the videos you can see down Craner Curves the mud and tracks where people have run off the track. First accident happened a few minutes after the track happened when a mini found the barriers.

Did the morning session with the AR1's on and swapped to slicks for the afternoon. The difference in grip is just crazy, just need to remember that slicks are on when on the out lap.Added a few videos, Came across a 490bhp Cupra who was trying to get some fast laps in and followed him for a few laps. Spoke to him after and he was quite surprised to see me following him in a TT. You can't see it so much on the video but he was leaving 11's out of all the slow corners being a 2WD car on A052's. That run ended with the car going into limp mode after the low fuel level caused fuel starvation at the off camber Melbourne loop, You can hear all the popping and banging the engine was making accelerating off the corner and Ignitron put the car into limp due to lean Lambda, exactly what it supposed to do.

Hopefully sort this issue soon as I have had a swirl pot to fit the car for over 18 months now. Managed a 1.47.5 on a clear lap on the AR'1 s without pushing it too much and did pretty much all the running on the day on a 1.8 bar boost map giving the engine an easier time.In the afternoon managed a 1.46.75 on a lap where I had to lift for a few cars with a best virtual lap of 1.45.28 . plenty more time to find exploring the crazy grip offered by slick tyres.

Fastest lap on slicks

View: https://youtu.be/zTR29sJ9I_Y

Fastest lap on AR1's

View: https://youtu.be/im93I6h2kYY

Few laps following a 490bhp Cupra

View: https://youtu.be/bY2XuJF_vjI

Did the morning session with the AR1's on and swapped to slicks for the afternoon. The difference in grip is just crazy, just need to remember that slicks are on when on the out lap.Added a few videos, Came across a 490bhp Cupra who was trying to get some fast laps in and followed him for a few laps. Spoke to him after and he was quite surprised to see me following him in a TT. You can't see it so much on the video but he was leaving 11's out of all the slow corners being a 2WD car on A052's. That run ended with the car going into limp mode after the low fuel level caused fuel starvation at the off camber Melbourne loop, You can hear all the popping and banging the engine was making accelerating off the corner and Ignitron put the car into limp due to lean Lambda, exactly what it supposed to do.

Hopefully sort this issue soon as I have had a swirl pot to fit the car for over 18 months now. Managed a 1.47.5 on a clear lap on the AR'1 s without pushing it too much and did pretty much all the running on the day on a 1.8 bar boost map giving the engine an easier time.In the afternoon managed a 1.46.75 on a lap where I had to lift for a few cars with a best virtual lap of 1.45.28 . plenty more time to find exploring the crazy grip offered by slick tyres.

Fastest lap on slicks

View: https://youtu.be/zTR29sJ9I_Y

Fastest lap on AR1's

View: https://youtu.be/im93I6h2kYY

Few laps following a 490bhp Cupra

View: https://youtu.be/bY2XuJF_vjI

Similar threads

- Replies

- 1

- Views

- 2K