A long overdue update but not a massively exciting one.

In terms of the new engine build, not a huge amount has happened but more on that later. Back in April the shifter bushes went, rendering the car useless. I wrote about that here:

http://www.audi-sport.net/xf/threads/sloppy-gear-lever-replacing-shifter-bushes.267914/#post-2707536

Then a little later, I bought the new ECS billet dog bone to replace the delrin bushed VF engineering dogbone I had (pretty much solid) but I knew I'd have to fix the gearbox thread that was on the edge last time I changed the dogbone. I bought a TimeSert kit as they are said be stronger than helicoil and better for applications of higher load. Not cheap but seem like a really good solution.

The delrin bushed VF dogbone which was super solid. Nice gear shifts but everything in the car vibrated:

What was left of the thread:

The kit with the new bolts etc

The process of adding the timesert means drilling out the old thread which is a bit daunting:

All done and feeling a lot nicer:

More recently, before our trip to the UK in June, I noticed the car was loosing a bit of water, later working out it was coming from the water pump. ******. I got together a new pump, tensioner, belt and rollers to do it along with a new auxiliary belt + tensioner when we got back in July. Bit of a pig of a job to do purely because of the lack of space and how tight the belt is to get on. Getting the engine mount bracket out is a bit of pain but I found dropping it down out of the bottom (after lowering the engine a touch) was easiest.

Water pump looking a bit worse for wear after the water top ups:

Belt didn't look ideal either to be honest:

Anyhow, got it all finished and full of coolant only to find it was leaking coolant still but now from another spot. This time the o-rings on the heater matrix connections. Once those were changed all seemed good but I spoke too soon. The radiator seemed to be leaking. Luckily someone local had a Nissens one in stock (would have preferred Valeo) so grabbed that. I fitted it today which wasn't too bad of a job at all other than the Nissens radiator is a lot more fragile than the OEM one so resulted in a few bent fins.

All together and the AH Fabs V2 intercooler still looking good - also showing the recently refurbished headlights (I used the 3M kit):

Fingers crossed this is the end of the water leaks. I'm sick of seeing the coolant low warning usually when I have no opportunity to stop and fill it up (of course, having to wait as well).

I also got some new AD08Rs fitted yesterday (while collecting the rad) - I opted for 235/40 this time. 245/40 might have been ideal but 235s are cheaper and lower profile - the 255/40 always seemed to look over tyred and too big for the car. I really like how it sits on the 235/40s. I'm off to Heasman's Steering on Tuesday to have the geo setup properly - they're a local place that are very well regarded so hopefully it all goes well.

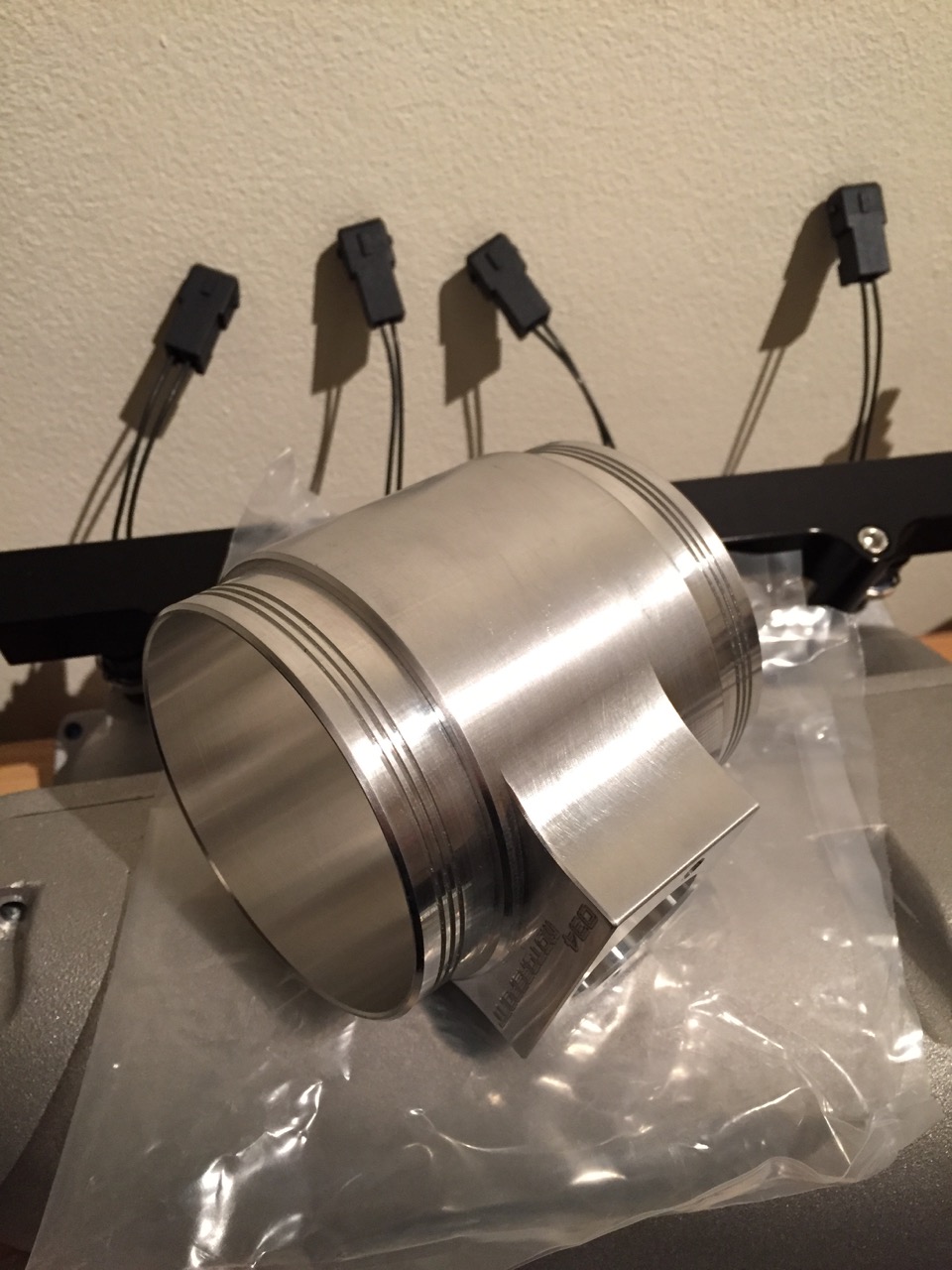

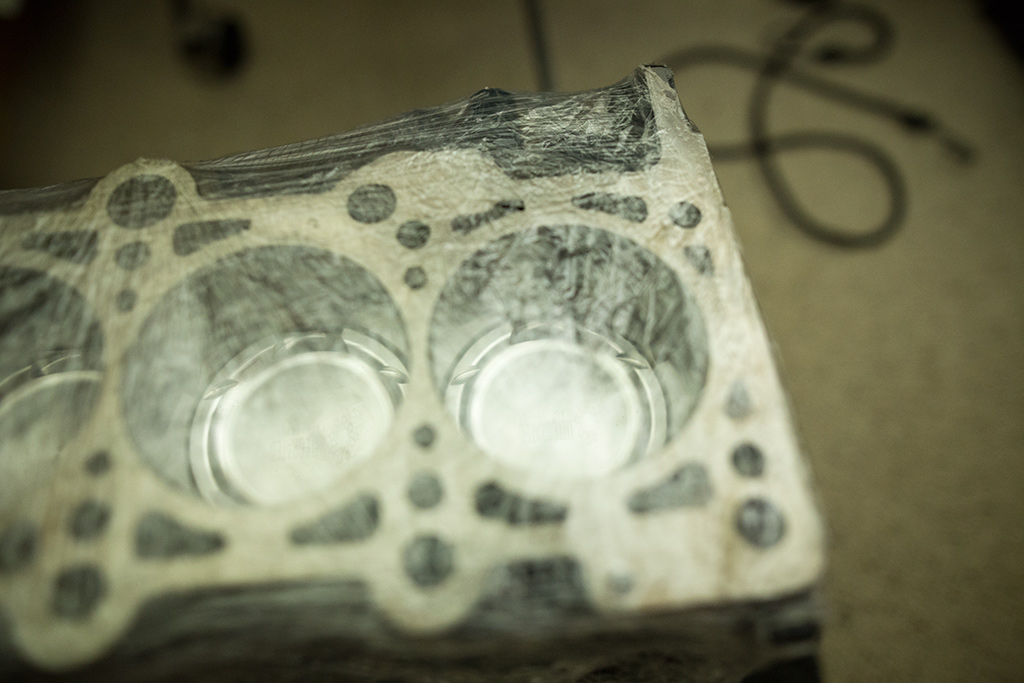

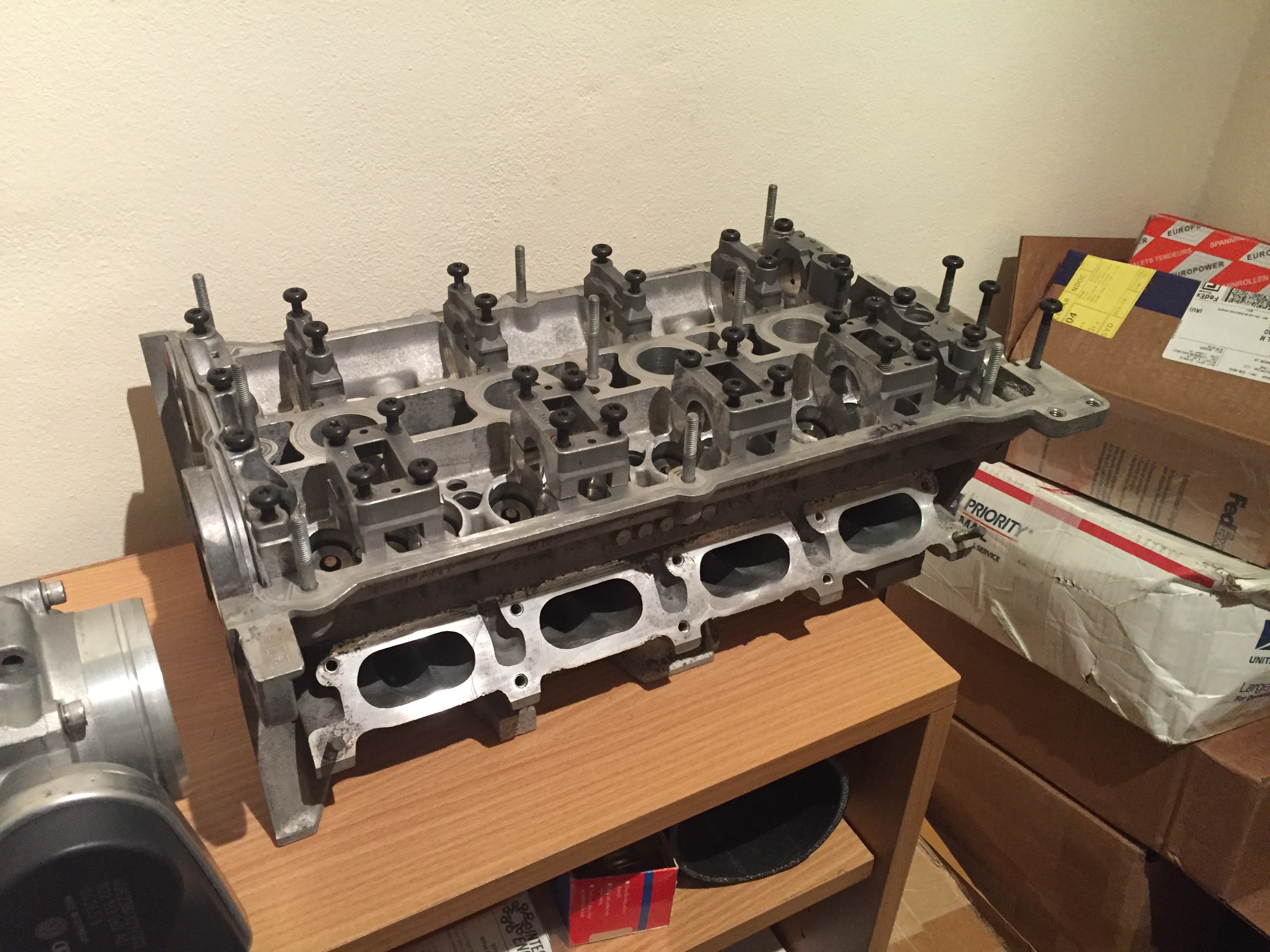

So.... onto the engine. I've finally got the head back. Spec is:

- ADR big port head

- IE spring kit and retainers

- Supertech +1mm inconnel single groove exhaust valves

- Supertech +1mm stainless single groove intake valves

It's not ported but that may be done later. The +1mm valves wouldn't have been my choice but at the time, the guy sorting out the head for me just went ahead and ordered them without consulting me. Oh well.

I've also bought a Wavetrac diff which is on it's way from the US.

The plan is:

- Order remaining parts required from ECS (small bits and bobs)

- Buy Link G4+ plug in ECU

- Assemble engine (bought an engine stand)

- Fit 8AN fuel lines from bay to boot

- Relocate battery

- Fit diff and steel forks to spare gearbox (for now - rebuild later)

- Get inlet pipes fabbed

- Get exhaust made

- Mapped by Micks Motorsport in Sydney

Also, the wife is pregnant so I need to get cracking and finish in 6 months. We need the parts room back as a bedroom

I'm going to keep the S3 though and buy a Mazda 3 or something as a family car.