What about an adapter for injectors? do I need them? ThanksIt seems its the ev1 type connector which the factory harness also uses.So should be all good

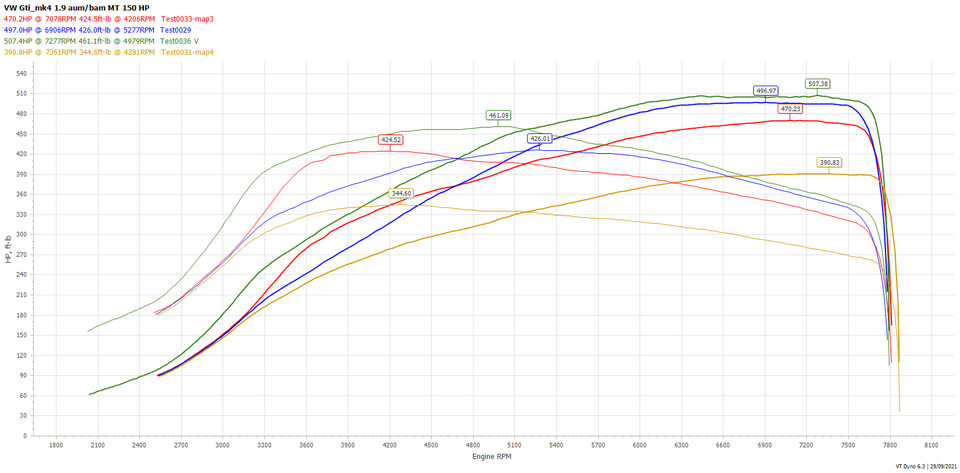

A couple of things about 1.8t engine building

- Thread starter Djordje1

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sorry ,maybe i did not write a understandable reply(english is not my native language)

That picture you posted shows a injector with jetronic/ev1 type socket.At least my S3 APY uses the same connector from the factory.If you are going to use the factory injector harness then you dont need an adapter.I hope i make sense

That picture you posted shows a injector with jetronic/ev1 type socket.At least my S3 APY uses the same connector from the factory.If you are going to use the factory injector harness then you dont need an adapter.I hope i make sense

Thank you so much @LordSidious it's very understandable. I'll also check that, but you should be right.

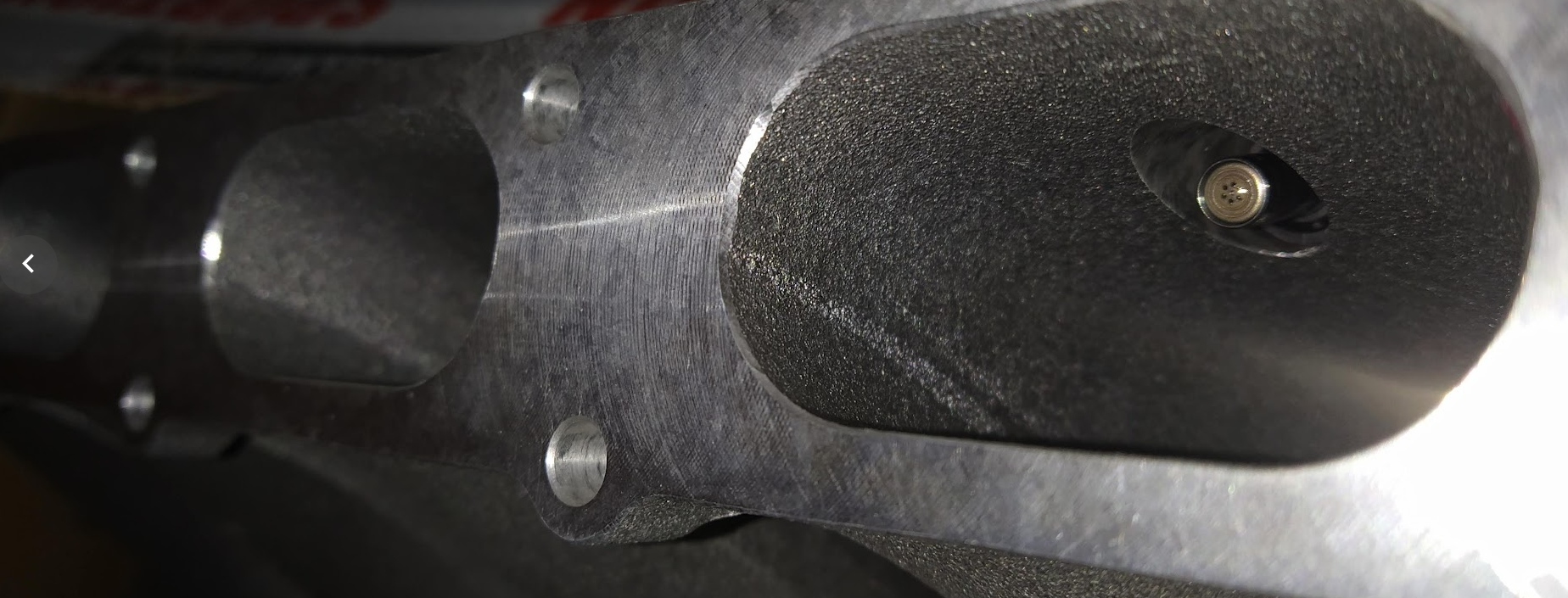

Also, do you know is this right related to the injector end position or if I need an extender?This is IE intake manifold... @<tuffty/> what do you think?

Thank you everyone,

Djordje

Also, do you know is this right related to the injector end position or if I need an extender?This is IE intake manifold... @<tuffty/> what do you think?

Thank you everyone,

Djordje

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

injectors look like they are clear spray pattern wise... you may need something to support whatever fuel rail solution you go for to extend the tops of the injector though

<tuffty/>

<tuffty/>

Do you think I'll need four of these?Not really sure...I'll ue IE fuelrail.injectors look like they are clear spray pattern wise... you may need something to support whatever fuel rail solution you go for to extend the tops of the injector though

<tuffty/>

IE says... NOTE: When installed on AMB engine codes with short injectors, IE 12mm Fuel Injector Extensions are required. IE Part Number: IEBAUU3

Thank you

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Not fitted that combo personally so cannot comment.... not sure how low the fuel rail will fit on the IE mani but you will know soon enough I guess

<tuffty/>

<tuffty/>

Definitely I'll order fuel rail and we will seeNot fitted that combo personally so cannot comment.... not sure how low the fuel rail will fit on the IE mani but you will know soon enough I guess

<tuffty/>

@S3AMJ Based on your suggestion and your current setup I decided to go without bov as well based on antisurge on the turbo,on the couple more places I read people suggested to keep without bov and keep system presurusse... Nor really sure what worng I did,but people are very limited and most of them says you need bov.Please help me to understand better your setup. Also Bill from badger5 said "Keep dv. Anti surge is not for dv surge on lift off"MAC Valve has more control on the bigger turbo stuff. N75 has its limitations. I’m not running a BOV on my build, that’s up to you. Garrett G series turbos already have anti surge comp housings, running a BOV is more for older gen stuff. I’m also not running my oil catch can back into the engine as it has a slight impact on reducing octane….. I’m obviously trying to squeeze every bhp out of my G30-770 turbo though, not save the environment.

Sent from my iPhone using Tapatalk

@<tuffty/> any thoughts?

Thanks

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Assuming you want input into this? basically Bill is saying that an anti surge compressor housing is there to mitigate compressor surge caused by trying to flow more air than the engine can consume.... compressor stall (the choo, choo, choo noise often mistakenly called wastegate chatter) is the result of not being able to release the pressure in the charge system when you lift off... this is the purpose of a blow off valve (atmos or DV)Also Bill from badger5 said "Keep dv. Anti surge is not for dv surge on lift off"

<tuffty/>

Thank you @<tuffty/> exactly snaping the air that coming back into turbo we are getting the noise, completely understand that part and the basics of how its works, but not sure if is it DV or BOV on @S3AMJ car hidden or is not exist at all. I'll go with some DV forge 50mm that you suggested a long time ago. Just wanted to make sure I understand correctly his setup and preference to go without bov and dv... pros and consAssuming you want input into this? basically Bill is saying that an anti surge compressor housing is there to mitigate compressor surge caused by trying to flow more air than the engine can consume.... compressor stall (the choo, choo, choo noise often mistakenly called wastegate chatter) is the result of not being able to release the pressure in the charge system when you lift off... this is the purpose of a blow off valve (atmos or DV)

<tuffty/>

Running your setup without BOV or DV will destroy your Turbo.Thank you @<tuffty/> exactly snaping the air that coming back into turbo we are getting the noise, completely understand that part and the basics of how its works, but not sure if is it DV or BOV on @S3AMJ car hidden or is not exist at all. I'll go with some DV forge 50mm that you suggested a long time ago. Just wanted to make sure I understand correctly his setup and preference to go without bov and dv... pros and cons

Tuffty nailed it giving you an explanation in simplest way possible.

I've been following UK & Greek Builds for years and never seen someone running without 'BOV' or 'DV' because their Turbo Compressor Housing has Anti-Surge.

I don’t run a BOV or DV on my build. Which has been built by Badger5. There are a few cars that I know of which also don’t run a BOV or DV. No problems so far.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Yes you can run without a BOV/DV but turbo life is largely dependant on what turbo you have... mid to large frame 'big turbos' have bigger shafts and tend to be more resilient to compressor stall... small frame turbos like K03/4 have shafts like cocktail sticks and will potentially shear under the right (wrong) circumstances...

Personally if there is no physical reason not to run one then run one... in Ash's case he is running multi nozzle WMI and basically anywhere he could fit a BOV meant that he would be potentially venting WMI into the engine bay so he doesn't run one...

I on the other hand while running WMI have fitted the BOV pre FMIC and my nozzle is post FMIC so I am not at risk of venting flammable liquid into the engine bay

<tuffty/>

Personally if there is no physical reason not to run one then run one... in Ash's case he is running multi nozzle WMI and basically anywhere he could fit a BOV meant that he would be potentially venting WMI into the engine bay so he doesn't run one...

I on the other hand while running WMI have fitted the BOV pre FMIC and my nozzle is post FMIC so I am not at risk of venting flammable liquid into the engine bay

<tuffty/>

Thank you guys a lot for your response I probably miss all your answers. I'll check them all carefully.

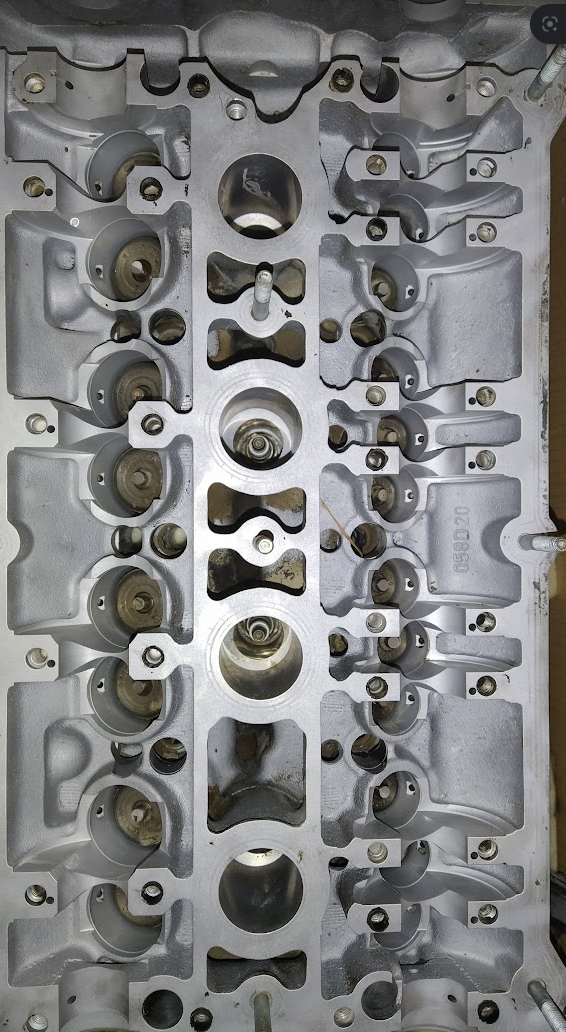

One thing I'm wondering about and wanted to check with you.I started cleaning head and slowly preparing for the build...

There is also couple more arrivals

I already bought rods 144x20 and JE pistons 82mm 9.25:1,

but if I decide to build a stroker

I will need couple different things...

1.Different pistons 83mm 9.5:1

2.TFSI,FSI crankshaft

3.transfer ring grear from 06a crankshaft to TFSI,FSI crankshaft

Rest of the things stay same?

I'm I right and what do you think? I still didn't start with build and have a time to make a stroker if I manage to change the pistons

Is it worth to make a stroker for g25-550?Can I expect more torque?

Please let me know what you honestly thing?

Thank you a lot

One thing I'm wondering about and wanted to check with you.I started cleaning head and slowly preparing for the build...

There is also couple more arrivals

I already bought rods 144x20 and JE pistons 82mm 9.25:1,

but if I decide to build a stroker

I will need couple different things...

1.Different pistons 83mm 9.5:1

2.TFSI,FSI crankshaft

3.transfer ring grear from 06a crankshaft to TFSI,FSI crankshaft

Rest of the things stay same?

I'm I right and what do you think? I still didn't start with build and have a time to make a stroker if I manage to change the pistons

Is it worth to make a stroker for g25-550?Can I expect more torque?

Please let me know what you honestly thing?

Thank you a lot

@desertstorm can you please clarify did you grind part of the pistons? Is that because of oil squirts? Is there any way to avoid that and buy different oil squirts or modify them to keep pistons without grinding? How does grinding affects the balance of the pistons?

@S3AMJ which pistons did you use for the stroker engine and what CR? I'm wondering now because I didn't start with build yet to build a stroker instead of a standard on. @<tuffty/> I know you are more for the vr6, but do you think is worth building a stroker for g25-550? Can I expect a bit more torque and benefits on fwd?

Thank you, everyone?,

Djordje

@S3AMJ which pistons did you use for the stroker engine and what CR? I'm wondering now because I didn't start with build yet to build a stroker instead of a standard on. @<tuffty/> I know you are more for the vr6, but do you think is worth building a stroker for g25-550? Can I expect a bit more torque and benefits on fwd?

Thank you, everyone?,

Djordje

The pistons have a cutout machined for the squirters, I measured the clearance and it was pretty small. I decided to trim the piston skirt a little more by grinding about 0.5mm more off the skirt where the squirter is. The amount of material I removed was very small and I did it on all 4 pistons . If I had bent the piston squirter out of the way a bit it would have been pointing in a different place . I suspect there are possibly detail differences between squirters mine were slightly different.

I think Badger 5 have done stroker G25-550 builds,Just did a search on there FB page for G25-550 stroker and got some hits.

I am not really sure you need more torque with a FWD car probably just end up with more wheelspin.

I think Badger 5 have done stroker G25-550 builds,Just did a search on there FB page for G25-550 stroker and got some hits.

I am not really sure you need more torque with a FWD car probably just end up with more wheelspin.

Thank you a lot for your quick reply. Maybe I'll do AWD conversion at some point, but for now, want to build my engine once and properly. I'll check all the results that you send and try to get more info from badger5 page...Thank you once again related to pistons grinding...Didn't know I have to grind that, but now I'm sure that is the right way to go. I thought, the pistons will fit perfectly, but probably not.The pistons have a cutout machined for the squirters, I measured the clearance and it was pretty small. I decided to trim the piston skirt a little more by grinding about 0.5mm more off the skirt where the squirter is. The amount of material I removed was very small and I did it on all 4 pistons . If I had bent the piston squirter out of the way a bit it would have been pointing in a different place . I suspect there are possibly detail differences between squirters mine were slightly different.

I think Badger 5 have done stroker G25-550 builds,Just did a search on there FB page for G25-550 stroker and got some hits.

I am not really sure you need more torque with a FWD car probably just end up with more wheelspin.

View attachment 260558

Have a nice day

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Doesn't DIY alterations of the pistons impact the weight and balance?The pistons have a cutout machined for the squirters, I measured the clearance and it was pretty small. I decided to trim the piston skirt a little more by grinding about 0.5mm more off the skirt where the squirter is. The amount of material I removed was very small and I did it on all 4 pistons . If I had bent the piston squirter out of the way a bit it would have been pointing in a different place . I suspect there are possibly detail differences between squirters mine were slightly different.

I think Badger 5 have done stroker G25-550 builds,Just did a search on there FB page for G25-550 stroker and got some hits.

I am not really sure you need more torque with a FWD car probably just end up with more wheelspin.

View attachment 260558

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

not overly... you can check the weight if you really want to... its how you balance pistons anyway... essentially by weight... out the box you would be surprised how different they are and even more so how close the squirter cut outs are... always worth checking these on stroker builds and almost always need to remove materialDoesn't DIY alterations of the pistons impact the weight and balance?

<tuffty/>

Thank you @<tuffty/> I have to pick up later FSI crankshaft with a stroke of 92.5mm I also retuned my pistons and I have to buy a new one.I'll probably go with JE pistons 83mm and 9.5:1 CR I already have 144x20 rods and thicker wall pins from JE as well....I'm wondering if is there anything else I need for stroker build?If I'm right all I need for the stroker that is different from the regular build isnot overly... you can check the weight if you really want to... its how you balance pistons anyway... essentially by weight... out the box you would be surprised how different they are and even more so how close the squirter cut outs are... always worth checking these on stroker builds and almost always need to remove material

<tuffty/>

1. FSI Crankshaft

2. 19Sprocket from the 06a(1.8t)

3.Pistons for the stroker.

All other parts are the same>? I don't need anything else to build a stroker. (Mean that is the only different?)

Thank you, everyone,

Djordje

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

You can't change caps just like that as it will need to be line bored... if going down that route buy billet caps and get the assembled line bored

<tuffty/>

<tuffty/>

Thank you a lot @<tuffty/> I think for my 500bhp it's not necessary to do it as you mentioned at some point.I just wanted to check if can this be used, but if not I'll stay on oem one... please let me know do I need anything else from the list to build a stroker? Please check my post 221You can't change caps just like that as it will need to be line bored... if going down that route buy billet caps and get the assembled line bored

<tuffty/>

Thanks,

Djordje

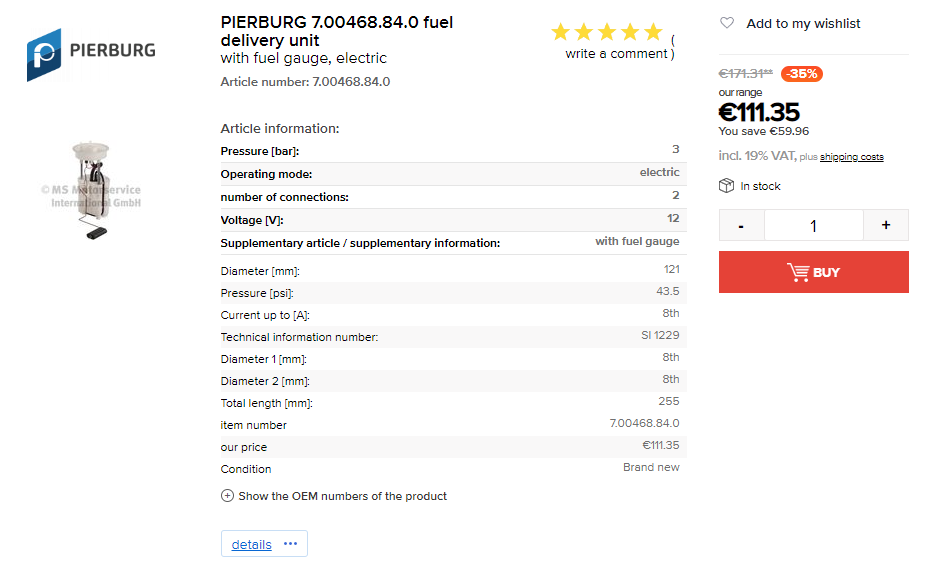

@<tuffty/> hey man.Wanted to ask related to the in-tank fuel pump. You mentioned I can stay on OEM one and just add 044 instead of the fuel filter...Related to the in-tank pump do I have to buy a new one, after the market like this one,

or just upgrade only pump for my setup...And which one to buy? Thanks

or just upgrade only pump for my setup...And which one to buy? Thanks

Don't get a DW65V go for the Sytec, they are cheaper and a lot more reliable. A good stock pump feeding an 044 in line pump will do 500bhp. A sytec or similar will help as it can flow more to feed the 044.DW65v or I think Bill sells Sytec they're a bit cheaper.

Thank you @desertstorm Ok then I have to keep the fuel delivery unit and just swap the current in-tank pump for Sytec. Right! btw relation to 044 do you have any diagram for wiring? Relay, fuses? Do I need an additional fuse or not?Don't get a DW65V go for the Sytec, they are cheaper and a lot more reliable. A good stock pump feeding an 044 in line pump will do 500bhp. A sytec or similar will help as it can flow more to feed the 044.

I took a feed from the existing fuel pump supply which operates a relay. You then just run a seperate 30A ignition switched feed through the relay contact to the 044. That way the 044 pump is only running when the in tank pump is running. I then later modified my 044 pump feed so it ran through a Solid State Relay that was controlled by the Ignitron ECU. This allows the ECU to control the 044 pump output using PWM .Thank you @desertstorm Ok then I have to keep the fuel delivery unit and just swap the current in-tank pump for Sytec. Right! btw relation to 044 do you have any diagram for wiring? Relay, fuses? Do I need an additional fuse or not?

Thanks a lot. I'll also check some photos from your thread. I hope I'll find something there.I took a feed from the existing fuel pump supply which operates a relay. You then just run a seperate 30A ignition switched feed through the relay contact to the 044. That way the 044 pump is only running when the in tank pump is running. I then later modified my 044 pump feed so it ran through a Solid State Relay that was controlled by the Ignitron ECU. This allows the ECU to control the 044 pump output using PWM .

Btw, can you or someone else confirm the head gasket for 83mm pistons/stroker?

- Thickness [mm]:0.9

- Diameter [mm]:83.3

- Installation thickness [mm]:0.9

- Seal design:Metal Layer Gasket

- additionally required article (article number):325,930

- ELRING:head gasket

- Item number:376,843

- Our price:€37.71

- Manufacturer item number:376,843

- Manufacturer:ELRING

- EAN number(s):4041248587324

- Condition Brand new

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Thank you @desertstorm Ok then I have to keep the fuel delivery unit and just swap the current in-tank pump for Sytec. Right! btw relation to 044 do you have any diagram for wiring? Relay, fuses? Do I need an additional fuse or not?

My minor modding thread

I must say that reading this thread is inspiring me and giving me great and wonderful ideas for my own! I may take an idea or two though, I hope that's ok with you tuffty Thats why its here mate :)

<tuffty/>

Hey guys  me again...Slowly getting there. I send my head to a machine shop, hope end of February I'll run the car

me again...Slowly getting there. I send my head to a machine shop, hope end of February I'll run the car  will see...

will see...

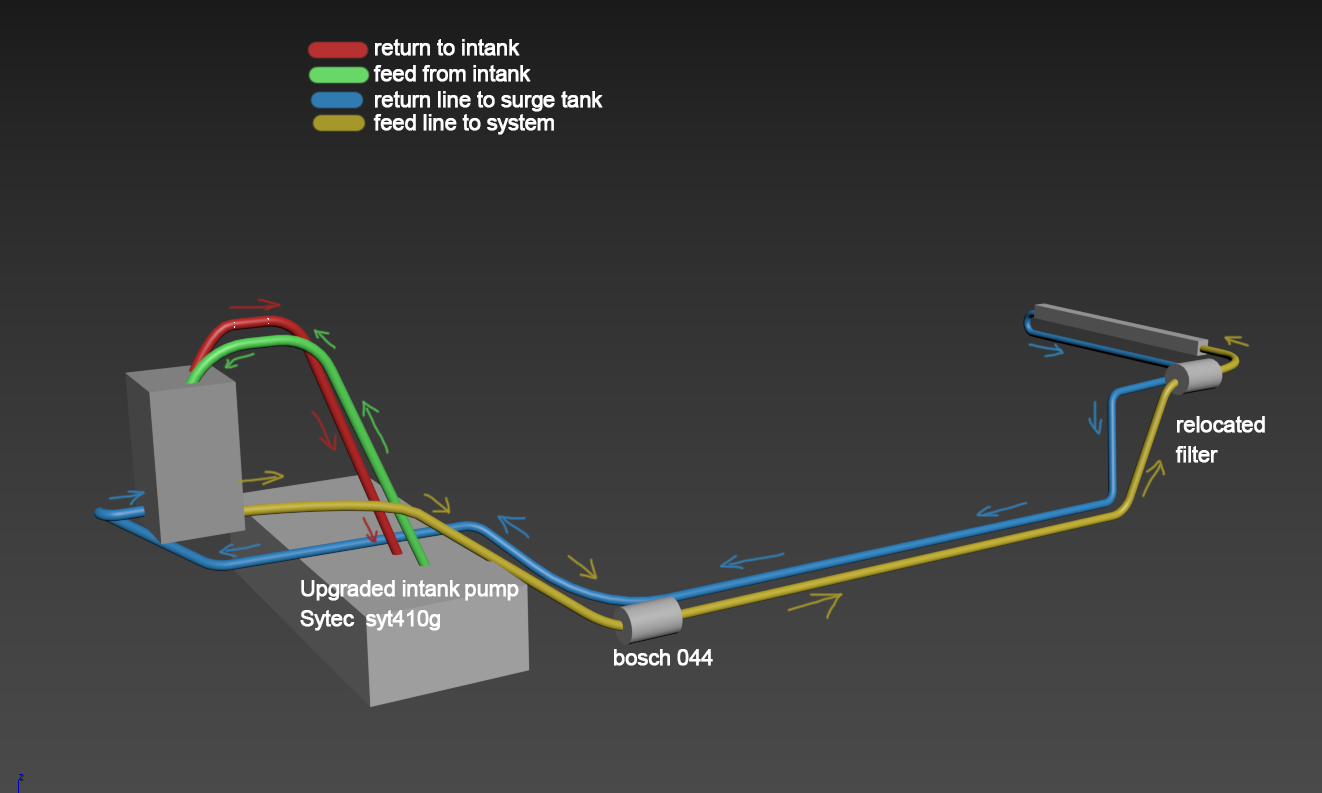

However, want to check something before I make any mistakes )) I'll probably go with a small compact surge tank. I don't want to go with extra capacity. Here is the diagram...

)) I'll probably go with a small compact surge tank. I don't want to go with extra capacity. Here is the diagram...

The question is.

1.Is this right way to do it?

2.Do I need one more lift up pump to surge tank on the green line

3.Do I need filter before surge tank on the green line

4.Do you think positions of connectos on the surge tank is good or I need to relocate something

I think sytec will be enough in combination with bosch 044,but still need to check that.

Thank you a lot!

@<tuffty/> @desertstorm @S3AMJ I'll really appreciate your answer! Thanks

However, want to check something before I make any mistakes

The question is.

1.Is this right way to do it?

2.Do I need one more lift up pump to surge tank on the green line

3.Do I need filter before surge tank on the green line

4.Do you think positions of connectos on the surge tank is good or I need to relocate something

I think sytec will be enough in combination with bosch 044,but still need to check that.

Thank you a lot!

@<tuffty/> @desertstorm @S3AMJ I'll really appreciate your answer! Thanks

That layout looks good. You don't need any other pumps.Hey guysme again...Slowly getting there. I send my head to a machine shop, hope end of February I'll run the car

will see...

However, want to check something before I make any mistakes)) I'll probably go with a small compact surge tank. I don't want to go with extra capacity. Here is the diagram...

The question is.

1.Is this right way to do it?

2.Do I need one more lift up pump to surge tank on the green line

3.Do I need filter before surge tank on the green line

4.Do you think positions of connectos on the surge tank is good or I need to relocate something

I think sytec will be enough in combination with bosch 044,but still need to check that.

View attachment 262243

Thank you a lot!

@<tuffty/> @desertstorm @S3AMJ I'll really appreciate your answer! Thanks

Thank you @desertstorm do you think I have to worry about warm fuel that is returning back into the surge tank?That layout looks good. You don't need any other pumps.

Btw, in relation to the bolts for the clutch. Is this good enough or do I need arp exclusively?

Please correct me if I'm wrong.

Related to oil temperature there is no sensor on 1.8t? It's just an oil pressure switch?

Yesterday I received OEM parts I bought for my build and I'm wondering do I need any oil temp sensor and which one? Can I use "10" from the diagram to attach the sensor maybe? If not Where and how to place the oil temp sensor? Also one of my friends suggested Bosch combined pressure temperature sensor ...

Thanks a lot!!!!!!

Last edited:

I wouldn't worry about warm fuel in the swirl pot, there is a lot of fuel moving back and forward between the tank and the swirl pot. You do need to think about the fuel line placing and making sure everything is safe and secure in the car, Think about what might happen in the event of an accident. You have fuel in the car, Don't use rubber hoses, fuel can permeate through the rubber and you will be able to smell it in the car all the time.

I used those Sachs bolts for the DMF on my car and had no issues.

That is just an oil pressure switch, In the MK1 TT there is an oil temperature sensor in the sump. The temperature of the oil is read by the cluster. Ignitron reads this value off the CAN bus packets that the cluster puts out. This tells you the oil temp of oil in the sump.

You can add an oil temperature sensor in the oil pressure test port and wire it into Ignitron as an extra sensor.

I used those Sachs bolts for the DMF on my car and had no issues.

That is just an oil pressure switch, In the MK1 TT there is an oil temperature sensor in the sump. The temperature of the oil is read by the cluster. Ignitron reads this value off the CAN bus packets that the cluster puts out. This tells you the oil temp of oil in the sump.

You can add an oil temperature sensor in the oil pressure test port and wire it into Ignitron as an extra sensor.

Thank you @desertstorm for quick response.I wouldn't worry about warm fuel in the swirl pot, there is a lot of fuel moving back and forward between the tank and the swirl pot. You do need to think about the fuel line placing and making sure everything is safe and secure in the car, Think about what might happen in the event of an accident. You have fuel in the car, Don't use rubber hoses, fuel can permeate through the rubber and you will be able to smell it in the car all the time.

I used those Sachs bolts for the DMF on my car and had no issues.

That is just an oil pressure switch, In the MK1 TT there is an oil temperature sensor in the sump. The temperature of the oil is read by the cluster. Ignitron reads this value off the CAN bus packets that the cluster puts out. This tells you the oil temp of oil in the sump.

You can add an oil temperature sensor in the oil pressure test port and wire it into Ignitron as an extra sensor.

The main idea for the swirl pot is to make one on the right side of the trunk...Like this...

And al the ptfe braided hose put true the hole under the carpet...I have sound insulation right now,but I'll remove on that place.because I want to keep back seats...

on the left-hand side of the trunk, I'll make the battery relocated from the front. I just wonder if is it harmful and how much to keep this regular battery inside the car. I can see you had an Odyssey battery and you change to a smaller one because Odyssey died. Is it gel one or regular? Honestly, Odyssey sounds like an amazing option on the paper, but I have a feeling that they have a lot of fails.

Want to secure the battery and tank and put them far from each other.

Luckily I have a 3d model of the whole car and I can plan my stuff from the office before I start with the realization

Sensor wise you mentioned.I have to check what is my options...Because I am on ECU master black I hope there is the same way to pull the data.

Btw,do I need need nordlock washer for the intake and exhaust manifold?

Where I can find bolts for the exhaust manifold?

Thanks a lot,

Djordje

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Not sure why you need a new fuel swirl pot in the boot.. seems like a fire-ball waiting to happen... don't folks with +500bhp setups just use an intank uprated fuel pump... (used to be dw65v and now Bill is selling Sytec as stock replacement) and additional inline tank.

Did they ever make an A3 8L with a battery in the boot? (I'm sure this was talked about recently??)

With the TT, the V6 and QS had a different spare tyre well, with a space for a battery.. a battery is also supposed to be able to vent to the outside... my TT just has a strap / clamp currently, but if i ever bother to get the car sorted if everything works okay... I will get a 'yellow top' battery, not that much more expensive than normal, but can be fitted any way up...

Did they ever make an A3 8L with a battery in the boot? (I'm sure this was talked about recently??)

With the TT, the V6 and QS had a different spare tyre well, with a space for a battery.. a battery is also supposed to be able to vent to the outside... my TT just has a strap / clamp currently, but if i ever bother to get the car sorted if everything works okay... I will get a 'yellow top' battery, not that much more expensive than normal, but can be fitted any way up...

I don't have a swirl pot in my TT and the only issues I have are when the fuel level goes below about 1/4 tank on long fast right hand corners the fuel goes to the other side of the tank and you start to get fuel starvation. I changed the odyssey for a 30Ah Exide AGM motorbike battery. This works a lot better than the Odyssey but is a few Kg heavier. Easier to mount in the boot and it doesn't need venting.

Not sure why you need a new fuel swirl pot in the boot.. seems like a fire-ball waiting to happen... don't folks with +500bhp setups just use an intank uprated fuel pump... (used to be dw65v and now Bill is selling Sytec as stock replacement) and additional inline tank.

Did they ever make an A3 8L with a battery in the boot? (I'm sure this was talked about recently??)

With the TT, the V6 and QS had a different spare tyre well, with a space for a battery.. a battery is also supposed to be able to vent to the outside... my TT just has a strap / clamp currently, but if i ever bother to get the car sorted if everything works okay... I will get a 'yellow top' battery, not that much more expensive than normal, but can be fitted any way up...

Thank you @Stuart B for your reply. I'll definitely go with a stronger in-tank setup.I just received my Sytec pump...I don't have a swirl pot in my TT and the only issues I have are when the fuel level goes below about 1/4 tank on long fast right hand corners the fuel goes to the other side of the tank and you start to get fuel starvation. I changed the odyssey for a 30Ah Exide AGM motorbike battery. This works a lot better than the Odyssey but is a few Kg heavier. Easier to mount in the boot and it doesn't need venting.

My plan is to buy some battery that doesn't require venting as Optima you mentioned or Exide as @desertstorm is using.

I need a swirl pot because...I spend a lot of money on the whole build and I don't want to think about what will happen If my fuel level goes under the line. I don't want to pray. I want to drive and don't think about that...I'll also do stainless steel swirl pot instead of aluminum, just to be more secure. I can place them into spare tire space as well...

@desertstorm Thank you for confirming that. That battery should be https://www.exidegroup.com/eu/en/battery/AGM12-31 I'm also wondering if we to avoid relocating the battery and keep it under the bonnet. How does this battery handle temperature? It's already smaller than my current battery...

Christmas is every month when you are doing the build

Thank you everyone!

Last edited:

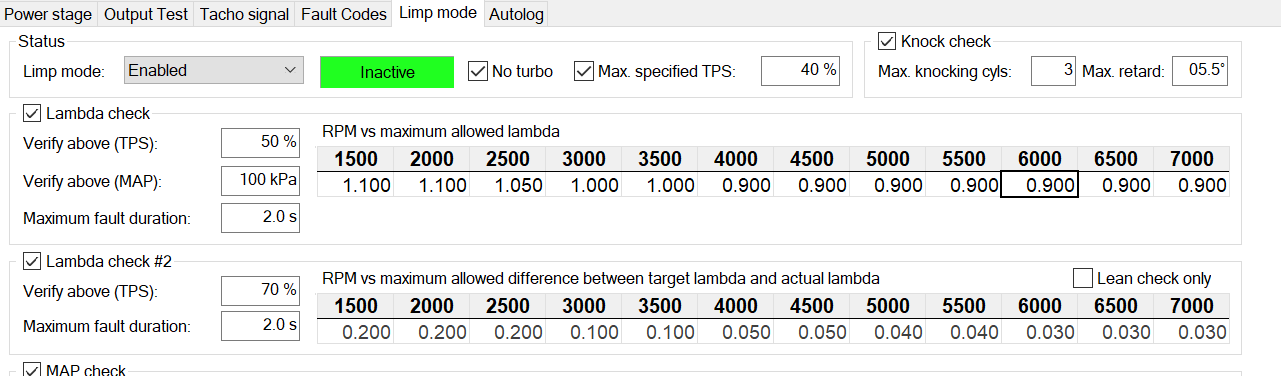

I would have thought you would have similar proitection maps on ECU master as Ignitron has if the engine is running lean. It's very obvious for me if the car starts suffering from fuel starvation on track. It will start popping in the exhaust and very shortly afterwards will go into limp mode, With the Lambda protection I have mapped. As soon as you slow down on track the fuel level is able to stabilise and you come into the pits.

There are many other things that could cause the engine to run lean such as fuel pump issues, fuel leaks, blockages, Fuel pump regulator problems like vacuum reference being lost. The monitoring covers from them all.

The Exide AGM batteries are fine under the bonnet .

There are many other things that could cause the engine to run lean such as fuel pump issues, fuel leaks, blockages, Fuel pump regulator problems like vacuum reference being lost. The monitoring covers from them all.

The Exide AGM batteries are fine under the bonnet .