for anyone intending to drop the subframe it is not a s bad as you might think.

I did this with only a couple of axle stands and trolley jack.

I wanted to leave the suspension in place so planned to disconnect the uprights from the upper wishbone, on the damaged side that turned out to be impossible as the wishbone had been twisted slighlty by the impact and the bolt was stuck fast. This meant I had to pull the shock casing as well.

difficult to see but both bolt and wishbone have a slight bend

in dropping the subframe it is possible to diconnect the brake hardline from the centre rear of the subframe and carefull unclip them from the frame. they are hanging down with some tape over the ends above.

you could leave the brakes on if you are only replaceing bushes but mine are being swapped over so they came off. Plan on replacing hardlines or softlines even if you don't want to. 10 year old brake components are soft and crumble easily when removing even with a brake spanner!

disconnect the back prop shaft from the rear diff, drop the centre diff bush housing as you need it out the way to access the handbrake if you are planning on pulling the whole thing.

Remember to disconnect the ABS sensors by lifting the back seat and pulling the plug, then pulling it through the body just in front of the subframe.

If removing the frame completely you can disconnect the handbrakes at the lever end from outside without having to remove inner trim.

three 13mm bolts drop the housing plate on the underside of the car, then two 13mm bolts inside can be undone with a ratchet ring spanner. then just unclip the cables.

the frame itself is held on with four 19mm bolts which are easily accessed, jsut make sure you are supporting the diff (as you should have done when you disconnected the prop ) and the frame.

A trolley jack under the main diff housing is sufficient.

pull the bolts and bob's your auntie..one two wheel A4!

I then went about stripping the Diff to fit the Quaife and replace the seals.

Seals first.

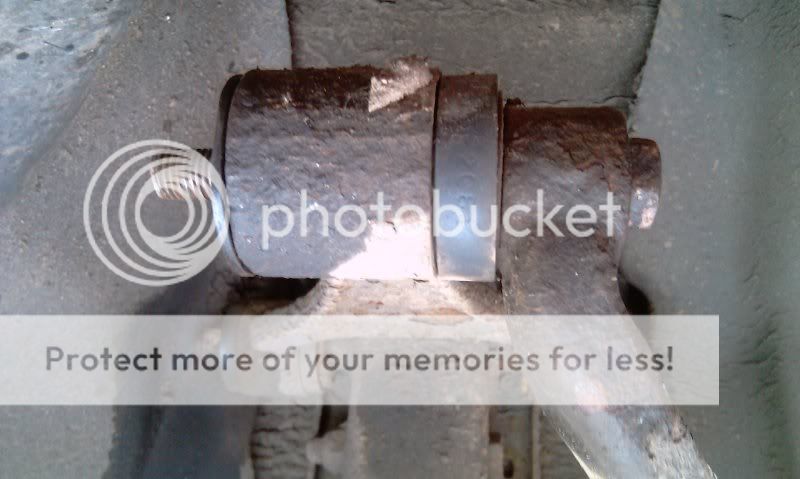

two hex bolts in the centre of the output flange release the flange completely.

seals can be prised out easy enough just don't scratch the surface.

use the old seals as a perfect drift to tap the new ones in. I always put some oil on the outside of the seal to stop the rubber turning on the cleaned surface it is going onto.

there is a fancy audi tool to refit but a flat plate, the old seal upside down and the new seal tap back into the correctgroove very easily. I don't think it is conincidence that the distance the seal sits in the bore is the exact same width of the seal itself. so if you tap the plate fluch with the old seal between the two it is exactly where it should be.

haven't refitted the flanges yet but a good clean and oil before refit is pretty self explainatory.

Diff.

Flanges off there are 15 or so 6 point hex studs holding the main case cover on.

whip them off and the only thing holding it in is a snug fit and an o ring. tap it off all the way round so it doesnt crush the o ring.

The diff now lifts out with surprising ease

anyone spot the deliberate mistake here?

(clue: output shafts are different size on the Quaife and the OEM!)

also don't attempt to use bearing pullers to remove the tapered roller bearings! they bend!

fitting the Quaife is fairly straigh forward, you need to remove the OEM crown gear and fit it to the ATB, you would be advised to get two new tapered roller bearings that hold the Diff in the case. you will need the exact diff code to match the bearings as there are two different RHS bearings and about 15 combinations of fitted washers! the wrong ones will see the diff too loose or too tight in the case when you refit it.

A good sluice out and refill with new diff oil is required after 100k miles as you can see by the treacle in mine.

have refitted all the polybushes to the new subframe and replaced the crappy little hardline and soft fitting with some short stainless braided hoses I have from a Mk2 Golf project (mainly as I can't find my brake pipe flaring tool!)

more to follow when I work out what I am doing with this Quaife that doesn't fit and the OEM one that now doesn't work!!