abstract97

New Member

Hi,

I've recently bought an a3 and it's suffering from a huge performance drop, it struggles to go above 40-50mph depending on the road and the revs don't budge when going up a hill, it's incredibly sluggish. I can hear the turbo spool and upon deceleration i can hear pressure being released and there is a slight tinny rattle. I've scoured these forums and the rest of the web for potential causes but each one has been a dead end.

The car has only done 60K and is still all OEM, apart from an induction kit that the previous owner fitted.

These are the following things I've checked and done.

- No smoke from exhaust

- No EML

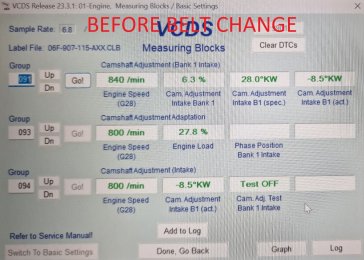

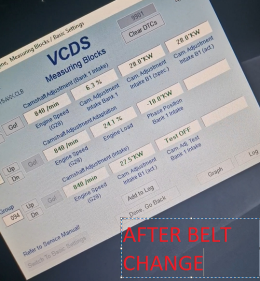

- Scanned with VCDS, only fault shown is relating to the haldex pump, don't think this would cause performance drop/no boost.

- Smoke tested, with no leaks found

- Checked all Intercooler pipework

- Checked vacuum lines, found a small crack so replaced them, these run between the manifold and vac pump.

- Replaced brake booster line

- Checked PCV system, no leaks

- Replaced diverter valve for a G generation

- Checked and cleaned MAF, obd data logs indicate this is operating normally

- N80/Evap has been checked and is operating normally

- O2 sensors removed to check Catalytic Converter flow and made no difference.

I've just taken off the downpipe as a final option today to check the condition of the turbo wastegate and it looks great. No play in either the turbine or the wastegate. The turbine spins freely and the wastegate is absolutely solid and doesn't move.

I've turned the car over with the downpipe off and the wastegate stays shut and doesn't open either. The actuator rod behind is in good condition and hasn't sheared off.

I'm out of ideas on what could be causing this now and i can't find any other potential causes.

Can anyone help?

I've recently bought an a3 and it's suffering from a huge performance drop, it struggles to go above 40-50mph depending on the road and the revs don't budge when going up a hill, it's incredibly sluggish. I can hear the turbo spool and upon deceleration i can hear pressure being released and there is a slight tinny rattle. I've scoured these forums and the rest of the web for potential causes but each one has been a dead end.

The car has only done 60K and is still all OEM, apart from an induction kit that the previous owner fitted.

These are the following things I've checked and done.

- No smoke from exhaust

- No EML

- Scanned with VCDS, only fault shown is relating to the haldex pump, don't think this would cause performance drop/no boost.

- Smoke tested, with no leaks found

- Checked all Intercooler pipework

- Checked vacuum lines, found a small crack so replaced them, these run between the manifold and vac pump.

- Replaced brake booster line

- Checked PCV system, no leaks

- Replaced diverter valve for a G generation

- Checked and cleaned MAF, obd data logs indicate this is operating normally

- N80/Evap has been checked and is operating normally

- O2 sensors removed to check Catalytic Converter flow and made no difference.

I've just taken off the downpipe as a final option today to check the condition of the turbo wastegate and it looks great. No play in either the turbine or the wastegate. The turbine spins freely and the wastegate is absolutely solid and doesn't move.

I've turned the car over with the downpipe off and the wastegate stays shut and doesn't open either. The actuator rod behind is in good condition and hasn't sheared off.

I'm out of ideas on what could be causing this now and i can't find any other potential causes.

Can anyone help?