Did a dyno day Sunday...

This was the first dyno run I have had since fitting the antisurge housing so was interested to see what she would do...

605hp and 520ish ftlbs... not convinced on the peak and they never revved the car out for the first two runs...

605 is not as high as she has done but I knew that bringing more boost in earlier would have an affect on top end power but after checking the logs afterwards I can see why she was struggling a bit...

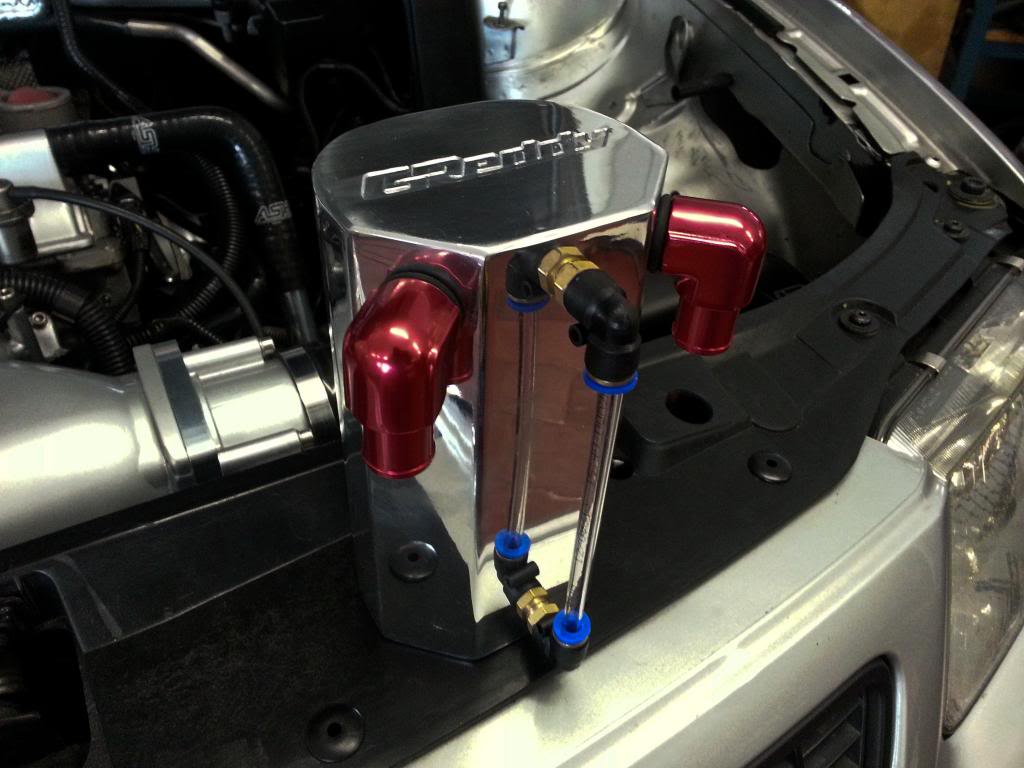

near 100 deg coolant temps and 42deg intake temps!!... yes I was using meth and it was on and working... the issue here really was as it turns out that the dyno fan wasn't the best...

Another log view also shows that ECU calculated power was down... this I think was due to not enough load on the dyno... something that can be seen from the hump as the revs climb on boost... high power and low load won't work the engine as hard... probably just as well considering the temps :/

On the way home I did a 3rd gear run just to reassure myself the engine was ok...

Clearly all ok there so will try and grab a run on Bill's dyno at the weekend to validate where she is...

There is a bit of an overshoot of boost when it hits just over 5k so I think I may just back the boost out a little and make it less aggressive....

Main reason being reliability... if the engine did actually produce over 500ftlbs of torque then thats quite a lot to ask of the transmission and would rather not be changing gearboxes twice a year.... I would also prefer to keep the engine in one piece... not exactly sure where the limit of the std mains caps is but I think I would rather not find out...

She was quick enough before I fitted the antisurge housing so will look to fine tune this area to lift up from that map but not be as aggressive as she currently is...

You will also notice she 'smokes' a little in the vid... this is purely from the fairly rich AFR I run... I could lean it out a bit but tbh its only really rich at full throttle and its not like she's lacking in power... rather be safe than sorry...

Surprisingly despite the IAT's and ECT's being high (and oil too!) the EGT's were still sensible and there was no timing pull so happy with that

Bit more fettling to do though which is fine by me.. would be bored other wise

<tuffty/>

.

.