- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

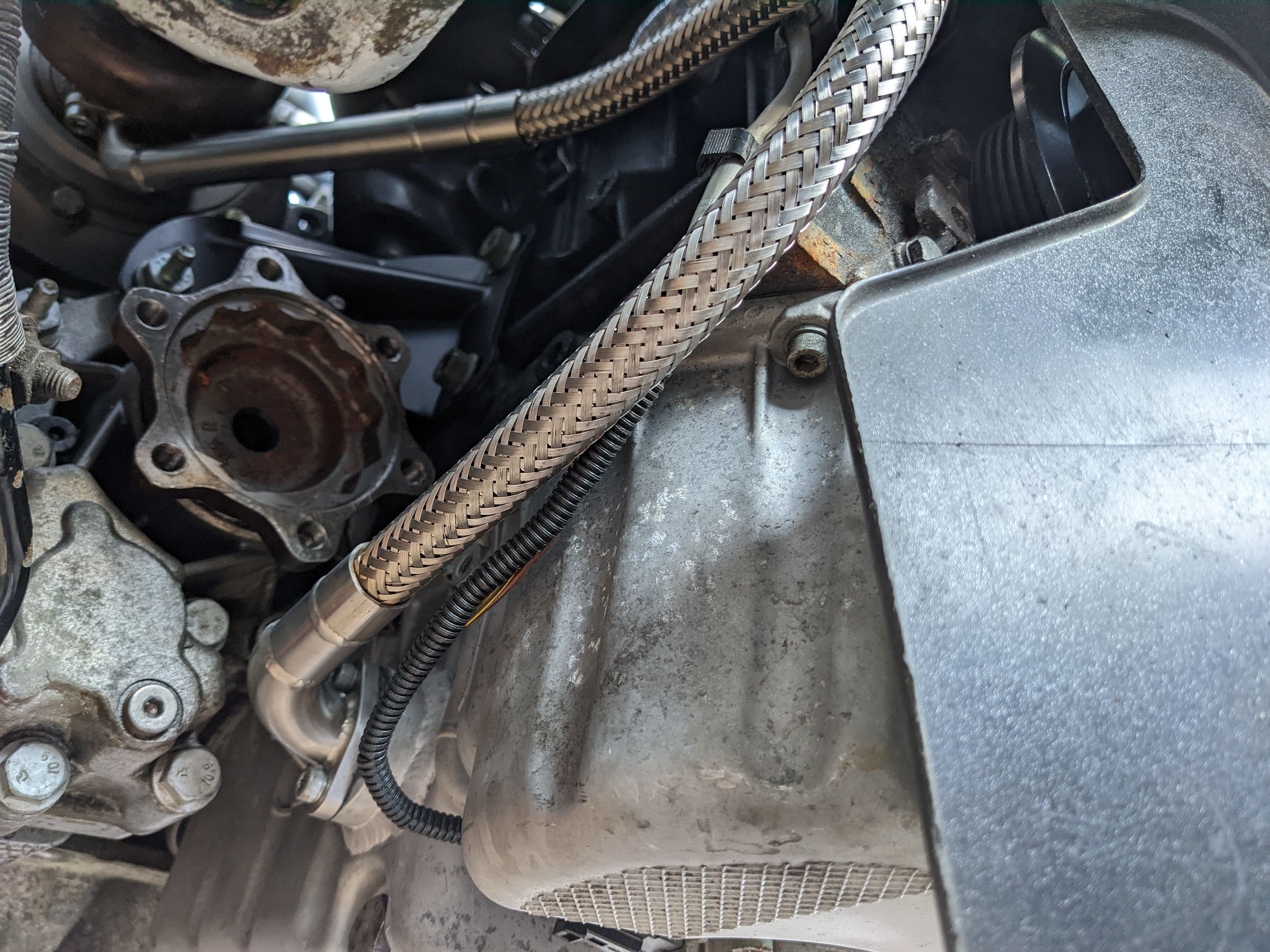

Flexi for the oil drain finally arrived so Alex welded it up...

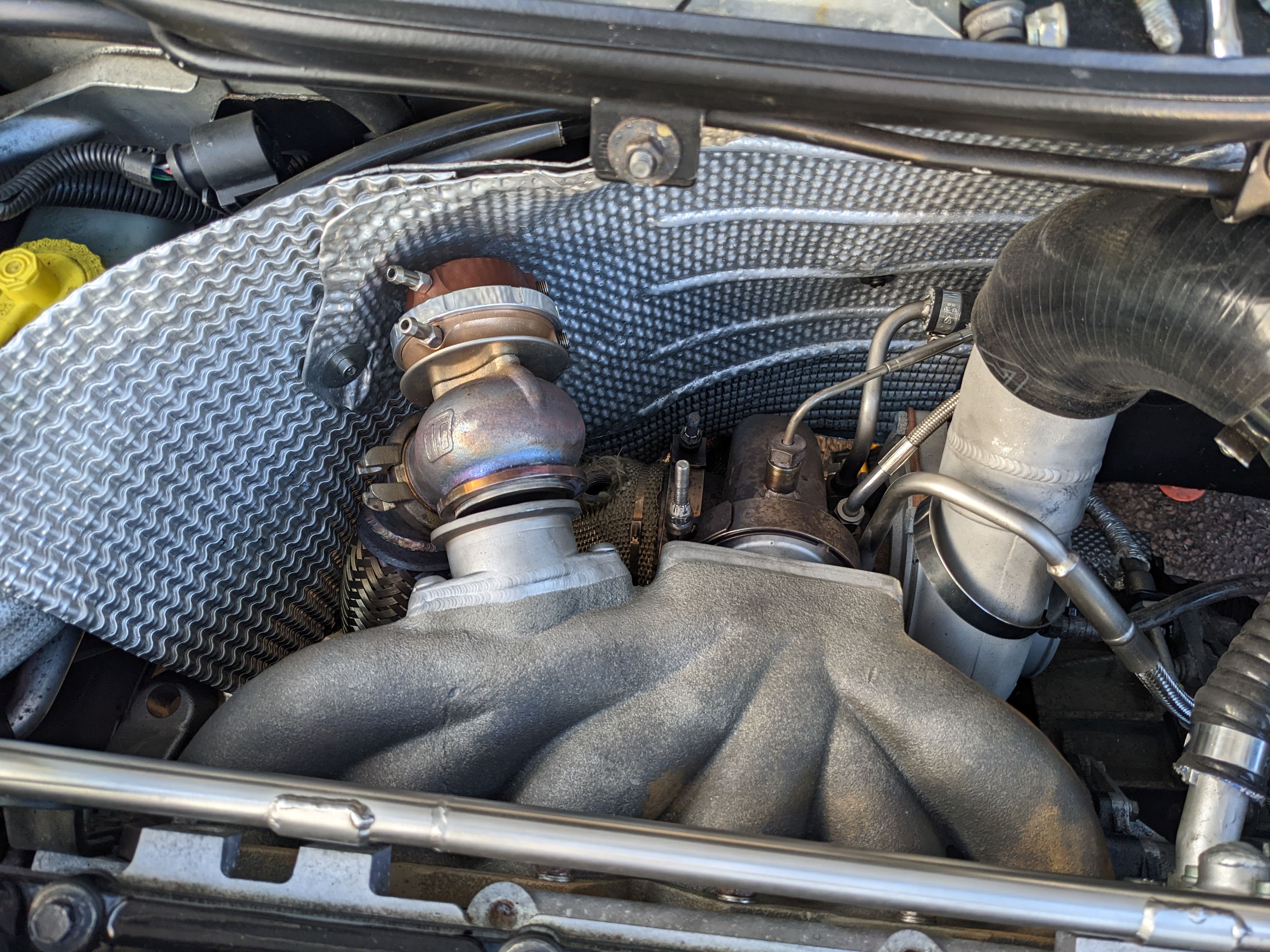

Happy days... cracked on putting the car back together...

Yes... the PAS pipework isn't where its supposed to but there is a reason for that...

Some idiot had put a gert gearbox in the way and not told it!!!.. I will need to get hold of the right return pipe at some point to replace this... but in the mean time the disc cutter came out to play

Need to clean up the ends a bit and swage then a little then add the loop bit from the piece I cut off to it... that will do until I have a more permeant solution ready...

Was quickly running out of light but managed to put quite a bit of the car back together... I still need to fill the engine with oil and sort the PAS out... then a spanner check before dropping the car to the ground and topping up fluids...

Home stretch but the weather is not looking too good for the next few days... have to see how that goes... I also picked up the spare DSG box this morning... looks ok and could connect to it using my test harness with no faults other than no comms (to be expected)

Looks like its a later TCU version that uses CAN only rather than K-Line for diagnostics like mine... plan is to do a full clean up on it... strip and clean the inside and inspect the clutch pack... the transfer box on this also has the right drive cup to use a ball type inner... a project for next year I think

<tuffty/>

Happy days... cracked on putting the car back together...

Yes... the PAS pipework isn't where its supposed to but there is a reason for that...

Some idiot had put a gert gearbox in the way and not told it!!!.. I will need to get hold of the right return pipe at some point to replace this... but in the mean time the disc cutter came out to play

Need to clean up the ends a bit and swage then a little then add the loop bit from the piece I cut off to it... that will do until I have a more permeant solution ready...

Was quickly running out of light but managed to put quite a bit of the car back together... I still need to fill the engine with oil and sort the PAS out... then a spanner check before dropping the car to the ground and topping up fluids...

Home stretch but the weather is not looking too good for the next few days... have to see how that goes... I also picked up the spare DSG box this morning... looks ok and could connect to it using my test harness with no faults other than no comms (to be expected)

Looks like its a later TCU version that uses CAN only rather than K-Line for diagnostics like mine... plan is to do a full clean up on it... strip and clean the inside and inspect the clutch pack... the transfer box on this also has the right drive cup to use a ball type inner... a project for next year I think

<tuffty/>